MobilityElectrification

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

Hi Everyone!!

Technical Tips on Advanced e-Axle are here.

It can materialize Higher Energy Efficiency, Weight Minimization,

Higher Continuous Power, Excellent Thermal Management, Volume

minimization & Lower NVH on Electrification.

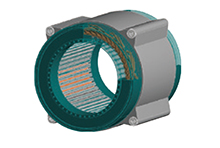

As a magnet fixing material for IPM motors, it achieves high heat resistance, high mechanical strength and high productivity. It is possible to fill even narrow gaps of 100 um level, contributing to higher performance of IPM motors.

Greatly contribution to the design flexibility and improving the functionality for EV/HEV drive motors.

Special material for insulation components.

Our ECP is suitable for insulation, stator-coil, armature, etc.

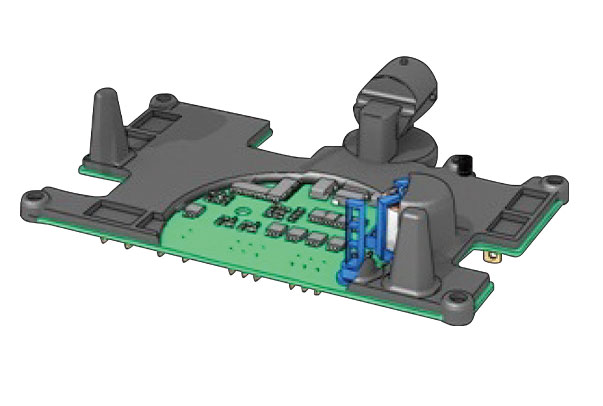

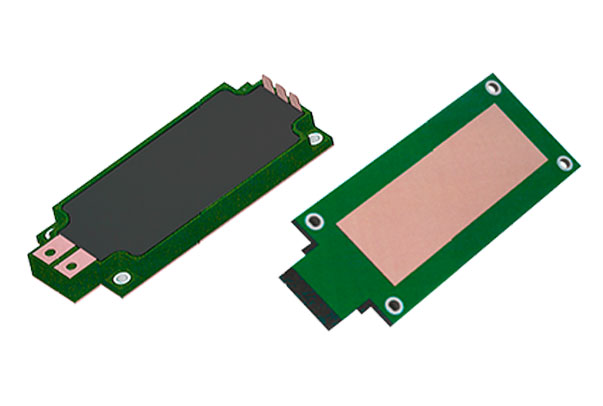

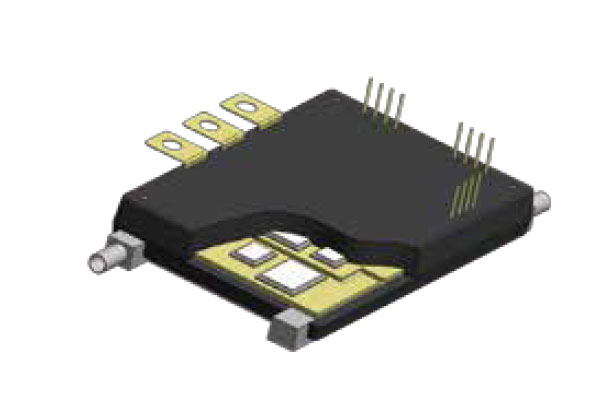

Molding compounds has excellent moldability, and contriibute to Downsizing, Higher Reliability of Various Modules by Direct Molding

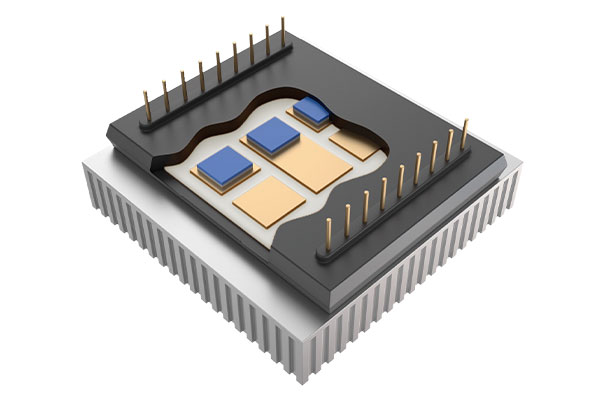

We have developped high reliabiity EMC(Epoxy molding compund) which has high heat resistance, heat dissipation and insulation perfomance for power device. We can also provide your PKG design flexiblity and high productivity by transfer molding system.

To meet the needs for high voltage / high current and solder replacement for power devices, we propose low electrical resistance and high thermal conductivity material with resin compounding and sintering technology.

Special material for insulation components.Our ECR is suitable for insulation, IBGT module, Ignition-coil, etc.

Reliable and high thermal conductive materials are made based on our formulas and production techniques. Adopting to LED Headlight and Power Module.

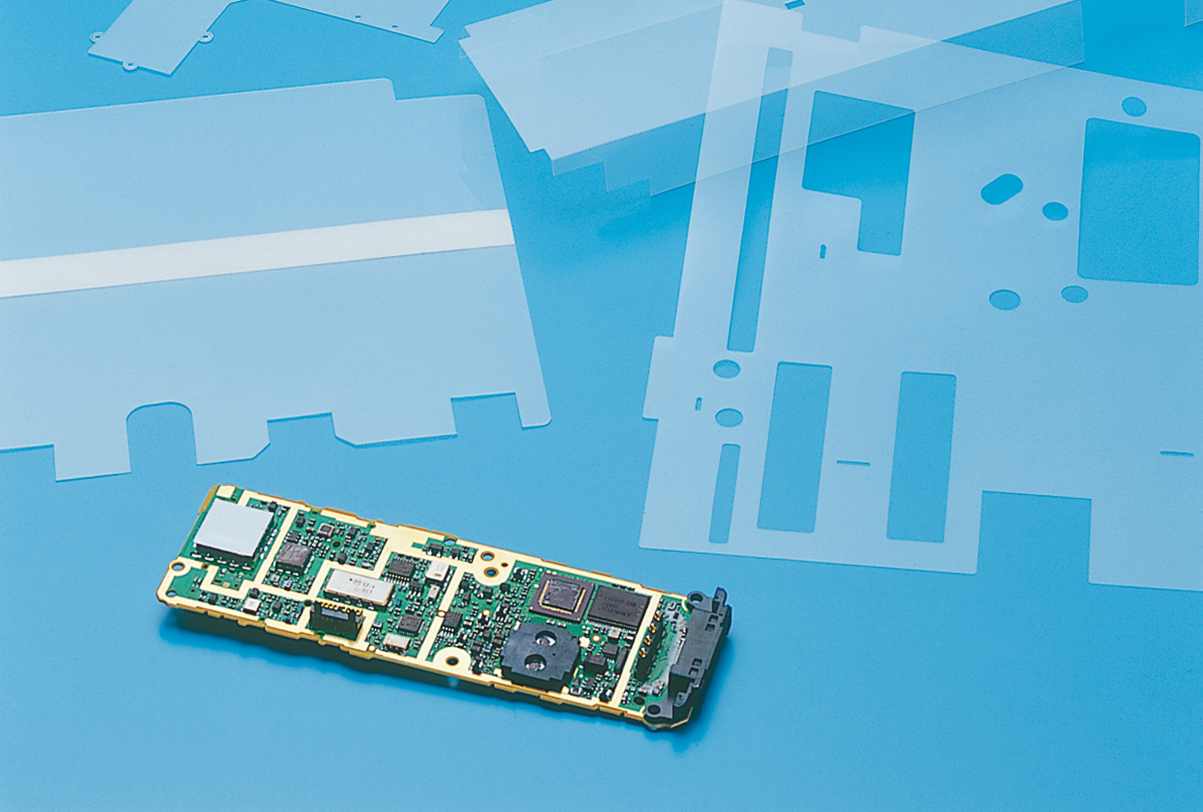

Special material for Bus-bar. Our materials are excellent insulasion property and suitable for bus-bar and stator coil.

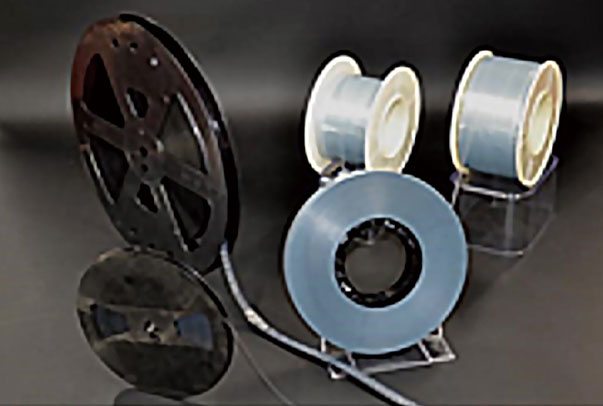

We provide fuctional products suitable for electric component mounting process and support production yield improvement, by proprietary base-film formulation, anti-electrostatic and adhesion property technology.

It is a halogen-free material that combines UL 94 (V-0, VTM0) and CTI: 0 (600 V or more). Applicable to high voltage equipment (OBC, inverter converters and power supplies).

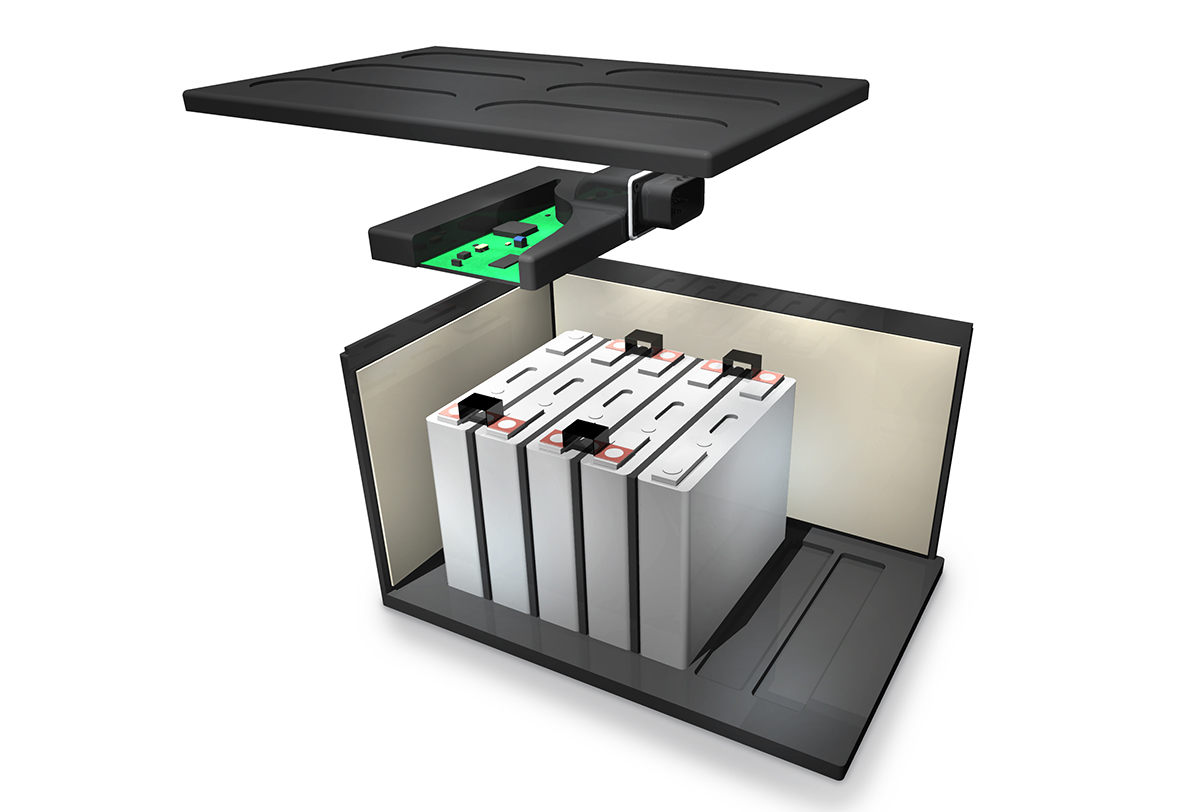

We're able to propose battery's solution conbined with our products having produced results. We are going to contribute for battery safety, design, flexibility and improved functionality.

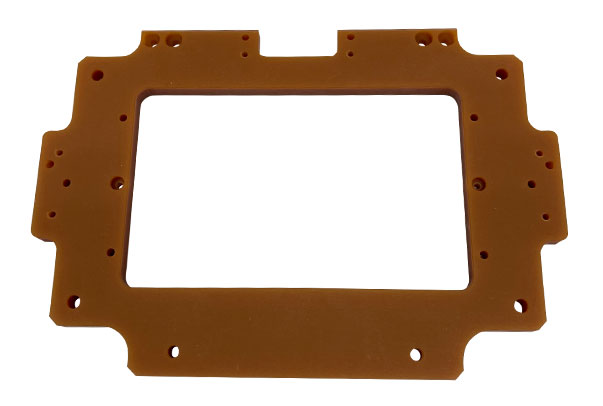

We propose the realization of resinification for various metal products. You can achive weight reduction, cost reduction, and metallic foreign matter reduction of existing metal products.