MobilityElectrification

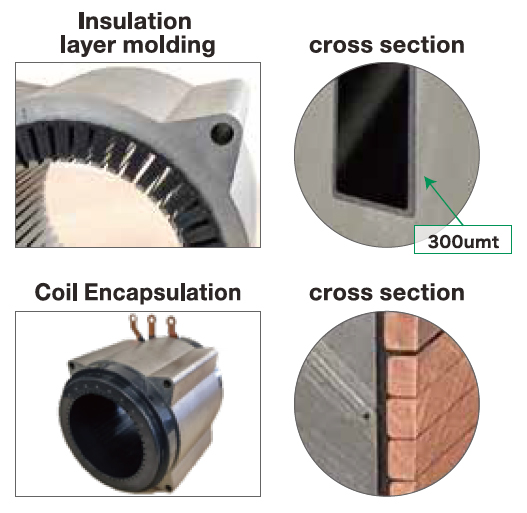

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

* Suitable not only for drive motors, but also for auxiliary motors and axial gap motors!

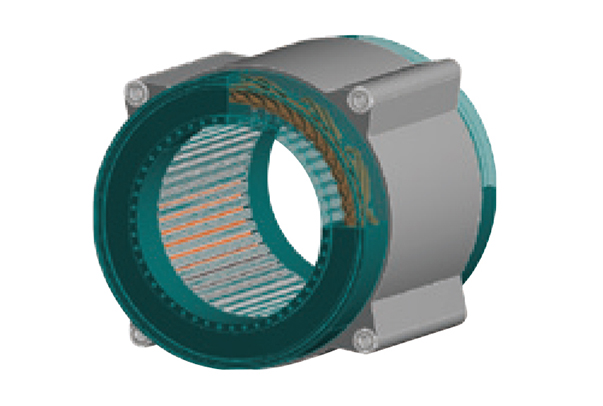

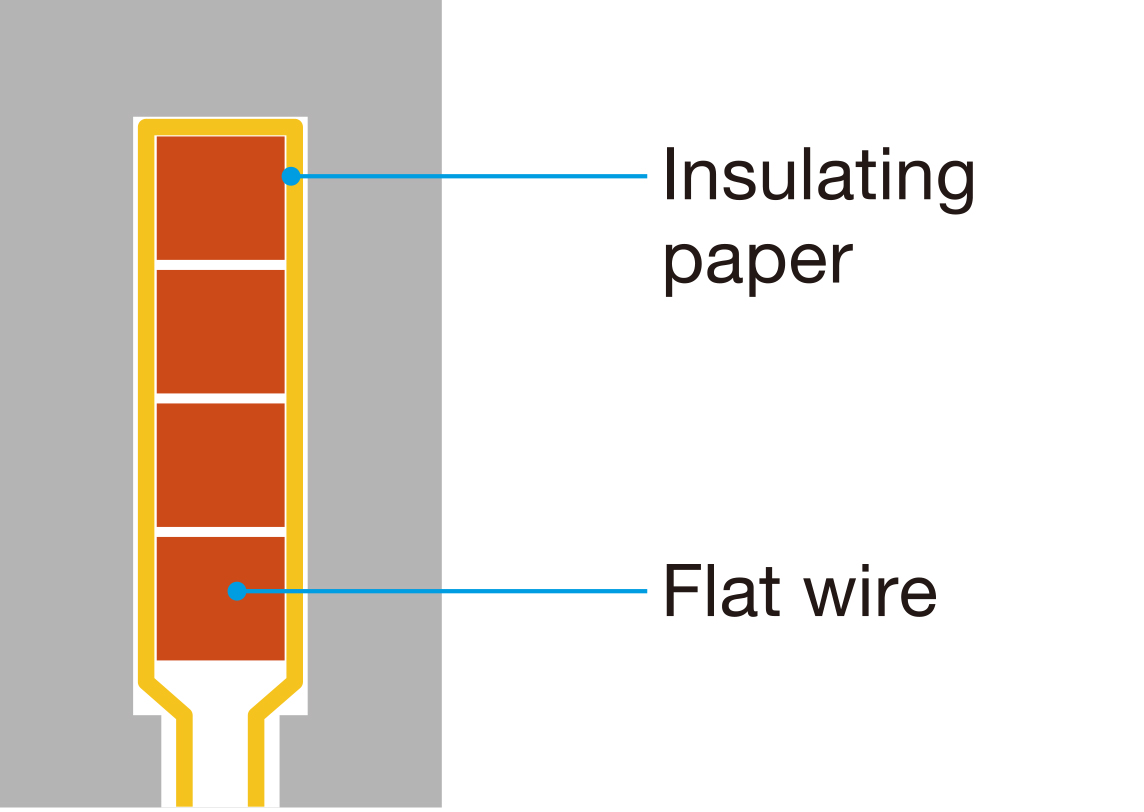

Insulating paper + liquid resin immersion, etc.

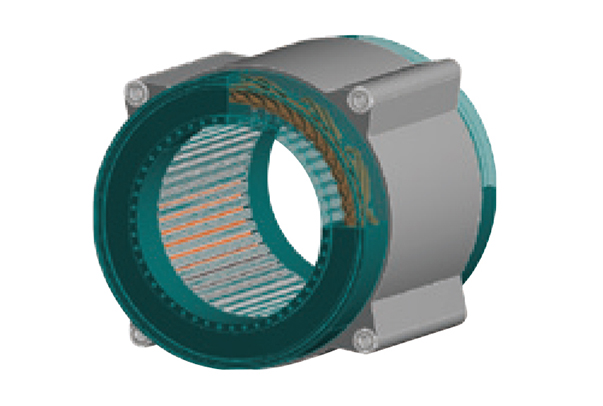

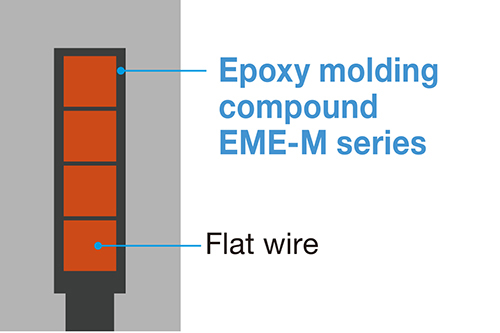

Encapsule with epoxy molding compound

No filling of coil gap

Filling of coil gap

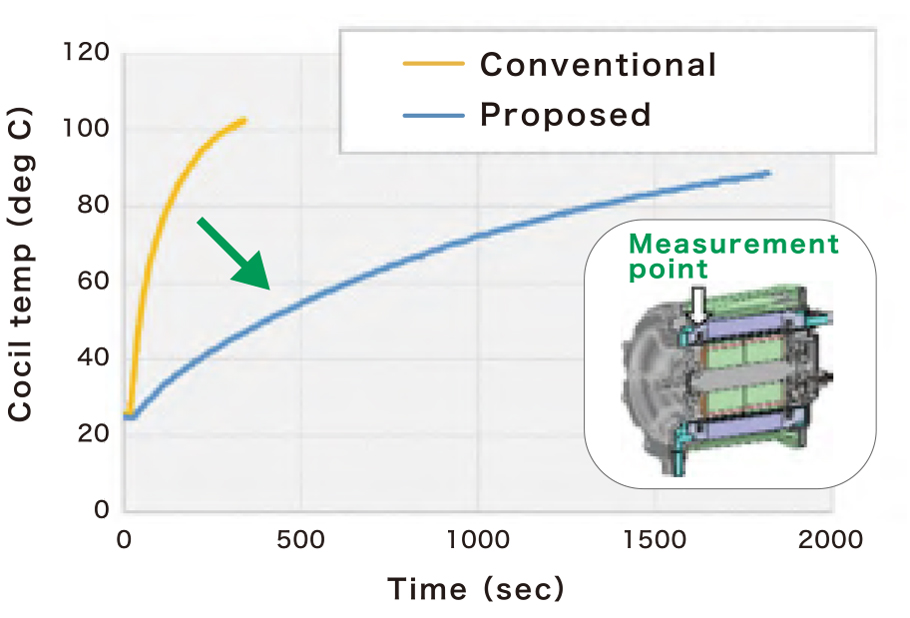

Coil temperature is reduced by coil encapsulation