MobilityElectrification

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

High heat resistance and high insulation thermosetting resin

improves functionality and reliability of electric power train.

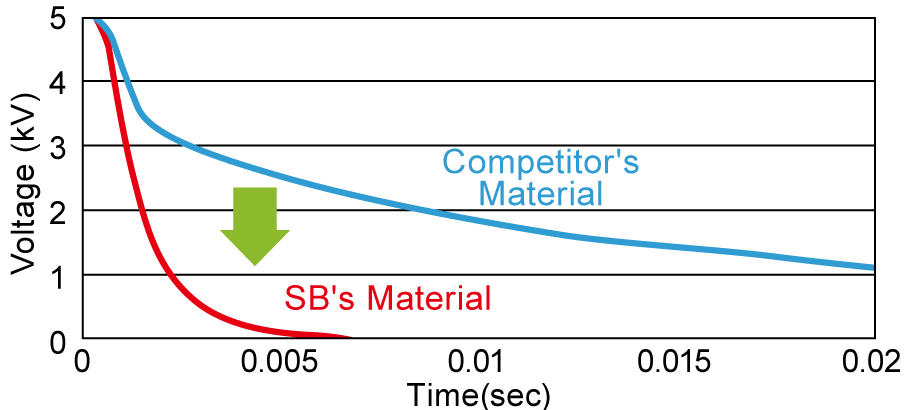

Relieves static electricity in a short time even in low humidity

| Items | Test method | Unit | Result |

|---|---|---|---|

| Surface resistance (Seal side) |

IEC 61340 | Ω | 1.0E+08 |

| Static decay time (Seal side) |

MIL-B-81705C (23℃30%RH) |

sec | <0.02 |

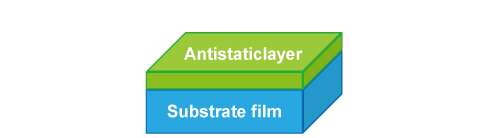

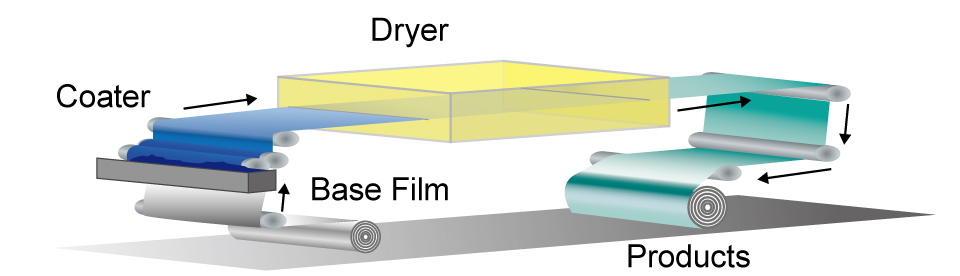

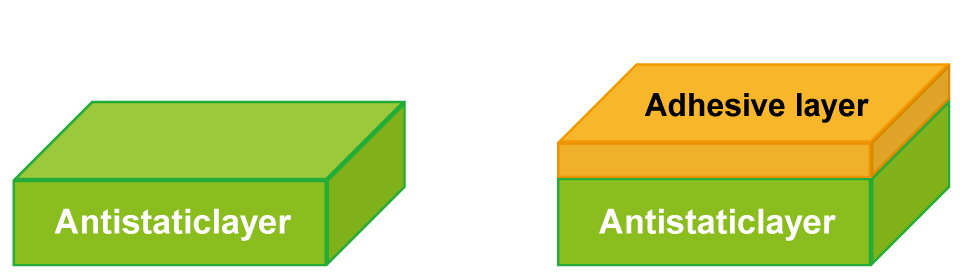

Antistatic function on the surface = Coating

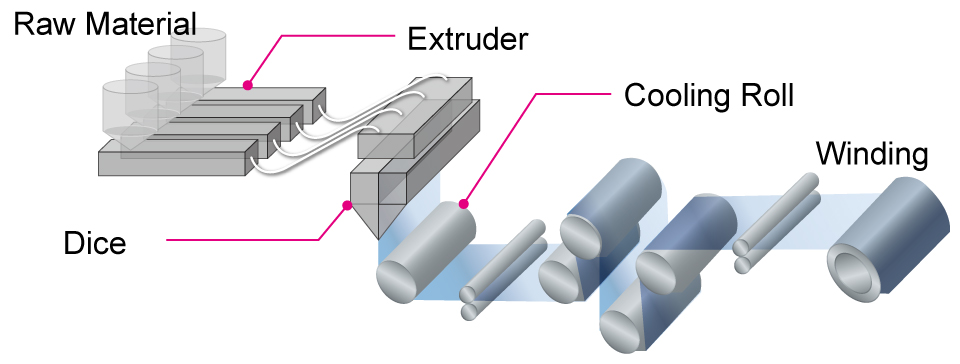

Antistatic function in bulk =Extrusion

<Static dissipative grade>

(SUMILITE® CSL-Z)

<Static dissipative grade>

(SUMILITE® FSL-N)