Products

|

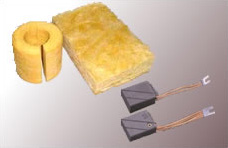

We offer phenolic resins as binder for friction materials which are used for brake linings, brake pads, clutch plates of transmission and others with superior heat resistance and adhesive performance. Plants

Laboratories

|

LCA Study

Here is an example of LCA study of an application in which our phenolic resin is used.

This shows the effect of reducing CO2 emissions when phenolic resins for friction material are replaced with biomass-based materials from conventional materials.

We use MiLCA, a globally recognized LCA calculation module for calculation. Please contact us for more information.

CO2 Emission Reduction Effect (Resin For Brake Friction Material)

| CO2 emissions (kg-CO2eq/kg) Equipment to 1 Passenger Car | Notes | |||

|---|---|---|---|---|

| Conventional Resin | Biomass Resin | Shorter Process Resin | ||

| Straight Powder Resin | 30% Lignin Modified Resin | Low Temp. Cure Resin | Shorten Process Resin: Assuming Energy reduction at product of pad by 30% | |

| Friction material: as a whole (a) <>Only Resin potion (weight%) |

N/A <0.42> |

N/A <0.36> |

N/A <0.42> |

Resin Content 0.1% |

| Pad manufacturing (b) | 2.6 | ← | 1.8 | Resin types do not matter to the numbers |

| Impact on driving (c) | 8.8 | ← | ← | Replacing cycle 50,000km |

| Disposal (incineration, recycling, etc.) (d) <>Only Resin potion (weight%) |

N/A <0.14> |

N/A <0.10> |

N/A <0.14> |

Resin Content 0.1% |

| Sum | 11.96 | <11.86> | <11.16> | |

| CO2 Reduction from Conventional material (Per vehicle) |

↓ 0.1kg |

↓ 0.8kg |

As 0.25 kg/pad x 4/front wheel | |

CO2 Reduction from Conventional material to Biomass Resin 0.09kg and

to Shorter Process Resinamount 0.8㎏-CO2eq per vehicle.

Remark

- CO2 emissions and reductions are only for resin in friction

- These data are representative values based on conditions in the tire production process and are not guaranteed.

|

(a)(b) |

(c) Cited by JAPIA_LCI_TOOL_USE_PHASE_GENERIC_Ver208 (d) CO2 emissions theoretically combusted |

Using MiLCA, LCA of automotive molded parts can now be calculated.

Please use this information for comparison with your company's current parts.

Features

High Performance, High Reliability

We offer various types of phenolic resins which provide superior heat resistance, good flexibility, high mechanical strength and good friction properties.

Applications

Automotive/Railways/Aircraft

Automotive Mechanical components

Brakes

Brake Linings, Brake Pads

Transmission

Clutch Facing, Paper Clutch Facing for MT/AT/DCT

Other Applications

Brake Shoe for train, Friction Materials for industrial brake

Expected Brake Pads Performance vs. Corresponding Type of Phenolic Resin

| Expected Friction Performance | ◀◀ Focus on Flexibility ◀◀ (Non-modified resin) ▶▶ Focus on Heat Resistance ▶▶ | |||||

|---|---|---|---|---|---|---|

| Low Noise |

Acryl mod.

|

Acryl mod.

|

Silicone mod.

|

Silicone mod.

|

||

Flexibility at low temp. |

||||||

| Water Resistance |

Water Repellency |

Aralkyl mod.

Heat

Resistance |

||||

| Wear Resistance |

Melamine mod.

Flame

Retardance |

|||||

| Moldability |

Fast Curing

Resin Fast Curing

|

|||||

| Eco- friendly |

Lignin mod.

Utilizing

Biomass |

|||||

Specifications

SUMILITERESIN®PR Series

| Grade | Melting point (°C) | Flow (mm) | Hexamine content | Advantage | Application |

|---|---|---|---|---|---|

| *PR-311 | 83 | 60 | Medium | High heat resistance,

high mechanical strength | Brake linings |

| PR-12687 | 78 | 45 | Medium | Flexibility | Brake linings (for oversized vehicles) |

| PR-13355 | 80 | 50 | Medium | Flexibility | Brake linings |

| PR-50064 | 90 | 20 | Medium | High heat resistance, high mechanical strength | Brake pads |

| PR-50069 | 95 | 0 | High | Flexibility | Brake linings, Railway brakes |

| PR-51510 | 88 | 35 | Medium | High heat resistance | Brake linings |

| PR-51794 | 102 | 12 | High | High heat resistance, high mechanical strength | Brake pads |

| PR-53724 | 93 | 33 | High | High heat resistance, high mechanical strength | Brake pads |

| PR-53497 | 98 | 27 | High | High heat resistance, Good mechanical strength | Brake pads |

| PR-54458A | 115 | 39 | Medium | High heat resistance | Brake pads |

| PR-55170 | 89 | 29 | High | High heat resistance | Brake pads |

| PR-51316M | 94 | 51 | Low | High heat resistance, Flexibility | Brake linings (for oversized vehicles) |

| PR-54529 | 92 | 38 | Medium | Water Repellency, Flexibility | Brake pads |

| PR-54529H | 94 | 36 | Medium | Water Repellency, Flexibility | Brake pads |

| PR-56291 | 100 | 18 | Medium | Water Repellency | Brake pads |

| PR-56291L | 92 | 40 | Medium | Water Repellency | Brake pads |

| PR-55291 | - | 40 | Medium | Flexibility | Brake pads |

| PR-55291A | - | 40 | Medium | Flexibility | Brake pads |

| PR-56341 | 97 | 27 | Medium | High heat resistance | Brake pads |

| PR-X20068 | - | 15 | Medium | Utilizing Biomass | Brake pads |

| PR-X20084 | - | 26 | Medium | Utilizing Biomass | Brake pads, Brake linings |

Remark

- * Please refer to the poisonous material control law(s) applicable in your country when you use this product.

- The data given above are not guaranteed values.

| Grade | Viscosity (MPa·s) | Resin content (%) | Solvent | Modification | Advantage |

|---|---|---|---|---|---|

| PR-50385 | 30 | 40 | Methanol | Cresol | High heat resistance, flexibility |

| PR-53123 | 10 | 45 | Methanol | Alkyl benzene | Good wear resistance |

| PR-53717 | 80 | 50 | Methanol /Toluene | Oil | Flexibility |

| PR-54562 | 14 | 48 | Methanol | Low molecular weight | Good impregnation performance, high durability |

| PR-55386 | 9 | 38 | Water | Melamine | Water soluble grade (environmental friendly) |

| PR-55536 | 11 | 44 | Acetone | Acrylic polymer | Flexibility |

Remark

- The data given above are not guaranteed values.

Topics More

- 2024/12/26 Products Development of SUMIKON® AM-3800 - a Diallyl Phthalate (DAP) molding compound for high voltage (800V) and high heat resistance

- 2024/10/18 Products SNC Industrial Laminates Sdn. Bhd. (Malaysia) Expansion of Liquid Phenolic Resin Supply

- 2024/10/16 Products Development of Fire Resistance Phenolic Molding Compounds for EV Batteries

- 2024/05/14 Products Development and Sales of Cyclo-Olefin Polymers (COP) to Meet Diverse Needs

- 2024/04/02 Products Completion ceremony of the new plant for phenolic molding compounds at Sumitomo Bakelite (Nantong) Co., Ltd.

Inquiry

Inquiry