December 26, 2024

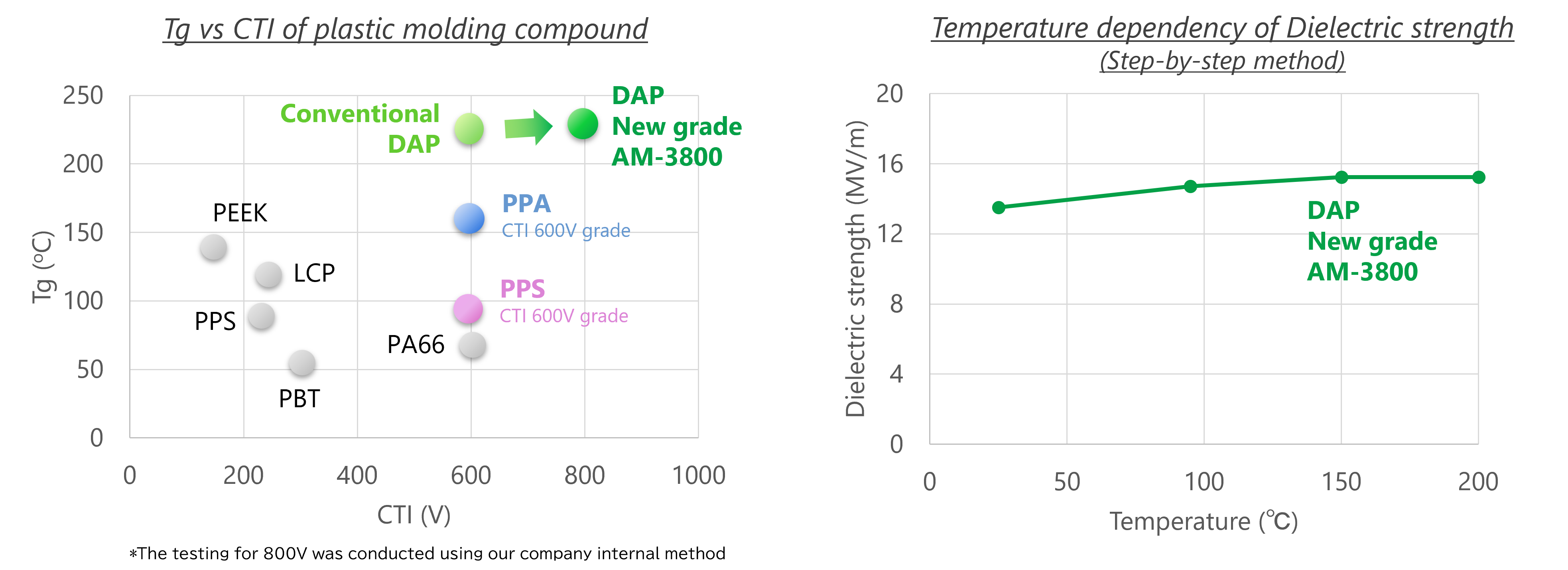

Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) is pleased to announce the development of SUMIKON® AM-3800, a new high insulation and high heat resistance molding compound, and the start of sample work. The molding compound uses diallyl phthalate (DAP) resin, which has excellent heat resistance and electrical insulation, and features high insulation with a Comparative Tracking Index (CTI) of 800 V or higher and heat resistance reaching a glass transition temperature (Tg) of 235°C. This will contribute to improving the safety and reliability of components in the electric vehicles (EVs) and renewable energy fields, where voltage is increasing.

Background

In recent years, as efforts towards carbon neutrality have advanced, the demand for electric vehicles (EVs) and renewable energy sources such as wind and solar power generation has rapidly expanded. In these fields, there has been a trend towards higher voltage systems, which increases the risk of insulation breakdown, short circuits, and malfunction of electrical components. Additionally, the increase in voltage also leads to higher heat generation, necessitating electrical components and insulation materials with higher insulation and heat resistance properties than before. Traditionally, engineering plastics such as PPS and PPA have been used, but there is growing interest in thermosetting plastics that offer even higher heat resistance and insulation properties.

High Insulation and High Heat Resistant Molding Compound - SUMIKON® AM-3800

|

We have launched a new compound grade AM-3800 in our diallyl phthalate (DAP) molding compound series (SUMIKON® AM). Diallyl phthalate is a thermosetting resin known for its excellent electrical insulation, heat resistance, and moisture resistance properties. The AM-3800 offers a high level of insulation with a CTI of 800V (Comparative Tracking Index, measured by our company internal method*), this makes it suitable for applications in high voltage components. It also has high heat resistance with a glass transition temperature (Tg) of 235°C. As a result, it maintains insulation breakdown strength equivalent to room temperature even in high-temperature environments of around 200°C. Since it maintains high insulation even in high-temperature atmospheres, it is expected to improve the safety and reliability of electrical components. * our company internal method – CTI value was measured by reversing the direction of the electrodes of the CTI testing equipment |

SUMIKON® AM-3800 |

We plan to continue enhancing the functionality of diallyl phthalate compounds using our compound formulation design technology. Additionally, we will maintain our collaboration with Osaka Soda Co., Ltd., a manufacturer of diallyl phthalate resins.

Reference

About the Future

|

In order to enhance our High Performance Plastic Products Business in the field of electric vehicle applications, we are currently undergoing a portfolio transformation towards high-value-added products. Starting from December 2024, we have commenced the distribution of samples of SUMIKON® AM-3800, produced by our mass-production scale line, to explore new demand opportunities and develop compounds with specific functionalities that align with our customers' needs. |

SUMIKON® AM-3800 |

Related Information

For inquiries on this information

Material Solutions Sales Division, Sumitomo Bakelite Co., Ltd.