Products

|

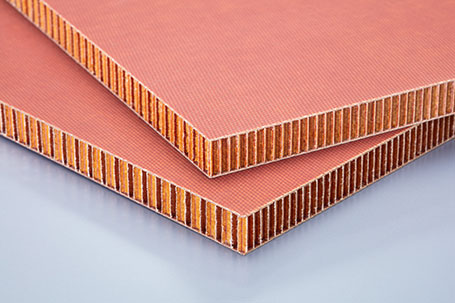

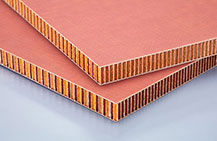

The plastic used for aircraft interiors must comply with aviation standards such as FAR set by the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). Phenolic resin which has excellent heat resistance and flame retardancy feature has been widely used as a component of honeycomb panels for aircraft interiors. We, who handle everything from phenolic resin research and development to manufacturing, have established mass production technology for honeycomb panels, which are the final products, in order to further demonstrate the capability of material development. Production Plant

Laboratory

|

Features

High production capacity and cost competitiveness

With the 36-opening hot press owned in Malaysia, it is possible to manufacture honeycomb flat panels of 20,000 m2/month with excellent cost competitiveness.

Excellent air/marine transportation access

With a location of 58km to Singapore Airport and 3km to Johor Port of Malaysia, it has good global access.

Variation of resin used and excellent R&D feedback ability

|

By vertically integrating Phenolic resin and prepreg development and manufacturing capabilities into the development and manufacturing of honeycomb flat panels, we can feed back the requirement of the final product to the materials and use new technologies such as lightweight/high-strength honeycomb panels, which enables us to propose new products. Surface smoothness for process and cost savingsWe achieve excellent honeycomb panel surface smoothness by manufacturing technology cultivated with conventional phenol laminated products. By omitting the filling/sanding process required for interior painting of conventional honeycomb panels, it is possible to reduce the process and manufacturing cost in our customer process. |

|

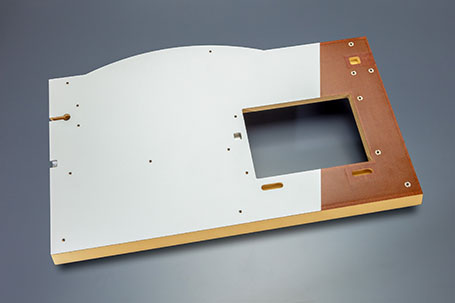

Providing highly cost competitive engineering panels by expanding processing capacity at the Malaysian plant

We can provide high quality and cost competitive engineering panels including various metals, urethane inserts, shape processing by NC, and edge processing in Malaysia.

Applications

Aircraft interior

Galleys, lavatories, overhead bins, crew rests, class dividers, various partitions, various monuments and cargo panels

Specifications

| Items | Unit | Method | Typical Value | |

|---|---|---|---|---|

| Aerial Weight | kg/m2 | - | 2.45 | |

| Panel Thickness | mm | - | 10 | |

| Long Beam** | T-dir. | N | ASTM-C393 | 837 |

| Short Beam | T-dir. | 1230 | ||

| Climing Drum Peel | T-dir. | ASTM-D1781 | 140 | |

| L-dir. | 100 | |||

| Heat Release Rate | Peak | kW/m2 | FAR 25.853 (d) | 31 |

| 2min Total | kWmin/m2 | 6 | ||

| Flammability 60sec Vertical |

Burn length | inch | 1.3 | |

| Extinguishing | sec | 1.0 | ||

| Drip time | sec | No drip | ||

| Smoke Density | - | <25 | ||

- * Panel composition

Core : Aramid paper honeycomb core, 1/8-inch cell, 3.0lb/ft3

Skin : #7781, 2 x 2 ply - ** LBF Span:Upper 254mm, Lower 508mm⇒ASTM-393 Quarter point

- 上The above mentioned values are not guaranteed but representative ones.

Technical Data

Topics More

- 2024/12/26 Products Development of SUMIKON® AM-3800 - a Diallyl Phthalate (DAP) molding compound for high voltage (800V) and high heat resistance

- 2024/10/18 Products SNC Industrial Laminates Sdn. Bhd. (Malaysia) Expansion of Liquid Phenolic Resin Supply

- 2024/10/16 Products Development of Fire Resistance Phenolic Molding Compounds for EV Batteries

- 2024/05/14 Products Development and Sales of Cyclo-Olefin Polymers (COP) to Meet Diverse Needs

- 2024/04/02 Products Completion ceremony of the new plant for phenolic molding compounds at Sumitomo Bakelite (Nantong) Co., Ltd.

Inquiry

Inquiry