Products

|

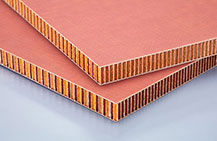

In addition to Acrylic-PVC alloy plate that has been used for railway interiors, SUMILITE® FRS that complies with FSH standards for aircraft interiors such as FAR set by the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) has launched. Color variations with evolved pearl/metallic feel contribute to improve the design and luxury of aircraft interiors. A new antibacterial version has also been added. Production Plant

Laboratory

|

Features

Experience with aircraft premium seats

We have a proven experience in premium and economy seating parts for global aircraft interior companies.

Various color variationsIn addition to experience in railways, aircraft interiors and automobile applications, we also have a lineup of color variations unique to aircraft premium interiors. Excellent chemical resistanceExcellent resistance to chemicals such as detergents and disinfectants including new Antibacterial grades. Excellent moldabilityExcellent moldability with a molding magnification of up to 5 times. |

|

Only one in Asia

We are the only manufacturer of PVC sheet for aircraft interiors with a manufacturing base in Asia.

Applications

Aircraft interior

Aircraft interiors and aircraft seat parts

Specifications

SUMILITE® FRS-5000 series (Low smoke aviation sheet)

| Parameter | Unit | Test Method | SUMILITE® FRS |

|---|---|---|---|

| Specific gravity | - | ASTM D 792 | 1.45 |

| Tensile strength | MPa | ASTM D 638 | 45 |

| Flexural strength | MPa | ASTM D 790 | 80 |

| Flexural modulus | 2850 | ||

| Izod impact strength | J/m | ASTM D 256 | 60 |

| Heat deflection temperature | ℃ | ASTM D 648 | 72 |

| Water Absorption | % | ISO 15512 | 0.34 |

| Vacuum forming | expansion rate* | 300% | |

- These are typical properties and are not intended for specification purpose.

- * The expansion rate is the comparison of the area of the original material sheet with thseu rface area of the products formed.

| Parameter | Test method | SUMILITE® FRS 3.0mm |

|---|---|---|

| Vertical Burn 60sec. | FAR 25.853 (a)(i) | Pass |

| Vertical Burn 12sec. | FAR 25.853 (a)(ii) | Pass |

| OSU Heat Release | FAR 25.853 (d)Part IV | Pass |

| Smoke Density | FAR 25.853 (d)Part V | Pass |

- These are typical properties and are not intended for specification purpose.

Technical Data

Topics More

- 2024/12/26 Products Development of SUMIKON® AM-3800 - a Diallyl Phthalate (DAP) molding compound for high voltage (800V) and high heat resistance

- 2024/10/18 Products SNC Industrial Laminates Sdn. Bhd. (Malaysia) Expansion of Liquid Phenolic Resin Supply

- 2024/10/16 Products Development of Fire Resistance Phenolic Molding Compounds for EV Batteries

- 2024/05/14 Products Development and Sales of Cyclo-Olefin Polymers (COP) to Meet Diverse Needs

- 2024/04/02 Products Completion ceremony of the new plant for phenolic molding compounds at Sumitomo Bakelite (Nantong) Co., Ltd.

Inquiry

Inquiry