Sustainable Procurement Policy

Taking the environment and society into consideration, we have established and released our Sustainable Procurement Policy, which applies to procurement activities by our Group companies. We ask not only Group companies but also our suppliers to act in accordance with the policy in order to build a sustainable supply chain. Responding to changes in what society expects of companies, the Sustainability Promotion Committee will continue to periodically review the content of the policy and revise it as necessary.

Sustainable Procurement Policy (revised November 1, 2024)

In order to fulfill our social responsibilities in business, the procurement departments of our Group engage in socially conscious procurement activities based on the following policies with the cooperation of our suppliers in the supply chain when procuring raw materials and equipment.

Sustainable Procurement

- We will conduct our procurement activities in respecting international standards as well as only in compliance with local laws and regulations with respect to the items such as human rights, labor, health and safety, ethics, and the environment. At the same time, we will request our business partners to take similar measures.

Major Sustainable Procurement Items

(1) Human rights, Labor, Safety and Health

- Prohibition of inhumane treatment such as child labor, forced labor, discrimination, and harassment

- Payment of appropriate wages (above minimum wage and meeting living wage) and allowances

- Appropriate working hours management and securing holidays

- Respect for freedom of association and the right to collective bargaining, etc

- Implementing responsible mineral sourcing (understanding the country of origin and distribution process, promoting sourcing from certified smelters and processors)

- Ensuring occupational health and safety

(2) Ethics, Information Security

- Promotion of fair and free competition (compliance with antitrust laws, etc.)

- Anti-corruption (anti-bribery, compliance with money laundering and terrorist financing regulations, elimination of relationships with anti-social forces, etc.)

- Personal information protection, prevention of leakage of confidential information

(3) Environment

- Preservation of the global environment

- Initiatives to reduce environmental impact and address climate change

- Reduction of energy consumption and greenhouse gas emissions

- Pollution prevention (air, water, soil)

- Use of sustainable water resources

- Waste reduction and efficient use of resources (reduce, reuse, recycle)

- Biodiversity conservation initiatives

- We have established the “Green Procurement Guideline” and carry out green procurement as art of efforts to reduce environmental impact.

Fair Transaction

- We select new suppliers on a fair and equitable basis.

- We work to build and maintain equal and trusting relationships with our suppliers and to conduct transactions of mutual benefit.

Stable Procurement

-

We consider it important that our suppliers’ endeavor:

(1) to maintain proper quality and enhance the level of technology;

(2) to meet delivery date;

(3) to price competitively; and

(4) to ensure stable supply. - Regarding Business Continuity Plan, we will separately establish contingency plans which include rules for reducing risks involved in procurement of raw materials and for actions to be taken if such risks occur.

Information Management and Control

- We proactively disclose information that is deemed necessary for transactions to the extent possible.

- We strictly manage and maintain confidentiality of information on purchases obtained from our suppliers.

Protection of Intellectual Property Rights

- We consider intellectual property rights to be one of the most important management assets and protect our own rights accordingly. Likewise, we respect the rights of others.

RBA Code of Conduct

- RBA (Responsible Business Alliance) Code of Conduct serves as a de facto standard to ensure that working conditions in the electronics industry supply chain are safe, that workers are treated with respect and dignity, and that business operations are environmentally responsible and conducted ethically. We are not a member of the RBA, but a large number of our customers are. Therefore, in addition to our own policies set forth above, we strive to conduct procurement activities in accordance with the RBA Code of Conduct.

- We request our suppliers to carry out their business activities in accordance with the RBA Code of Conduct.

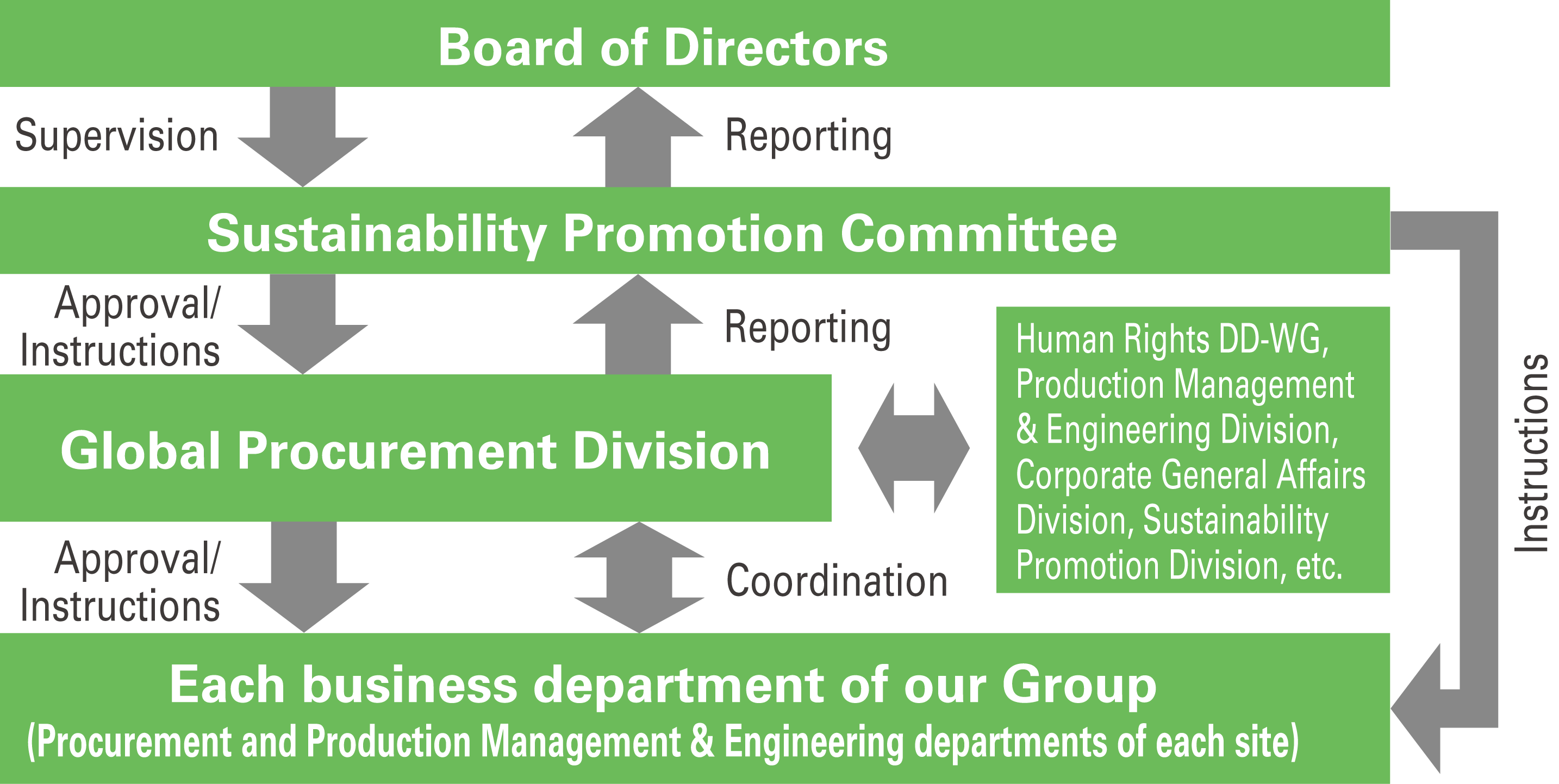

Sustainable Procurement Framework

- With regard to the promotion of sustainable procurement, the Global Procurement Division, under the management of the Sustainability Promotion Committee, promotes initiatives in cooperation with related corporate departments and other organizations.

Sustainable Procurement Initiatives

Relationships with Our Suppliers

- The Global Procurement Division is in overall charge of the purchasing of raw materials, fuel, and equipment for use at our Company’s plants and our Group companies worldwide.

- In selecting suppliers to purchase raw materials, equipment, etc., we have established selection criteria in our internal rules, and based on fair and impartial judgment of all criteria, we make decisions on the commencement of transactions based on established procedures. Our criteria for selecting business partners include their CSR and reduction of environmental impact initiatives. We are convinced that it is important to establish a relationship of equality and mutual trust with every business partner and that transactions should be beneficial to both parties.

Response to Compliance

- When conducting business, we strive to comply with laws, regulations, and social norms in Japan and overseas, and also ask our business partners to do the same.

- In principle, we ask each of our business partners from which we purchase items such as equipment or raw materials to conclude a basic contract, requiring the contracting parties to comply with laws and regulations related to human rights, labor, health and safety, ethics, etc., protect the environment, and fulfill their corporate social responsibilities (CSR).

- We have established company rules requiring that we check whether new raw materials comply with chemical substance controls both domestically and internationally, and new raw materials are not adopted unless they conform to these controls. Relevant departments internally work closely together to investigate and make sure that we do not violate chemical substance controls.

- When commencing transactions, we check whether the Act against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors applies and if it does, we commence the transaction in accordance with this law and the relevant company rules. If we find that this law applies to existing transactions, we immediately take measures to ensure the legality of these transactions under this law.

Carbon Neutrality Initiatives

- As an initiative toward achieving carbon neutrality, we have already secured and contracted green power for our domestic business sites for 2024 and are working to secure contracts for 2025. We have also coordinated efforts with the relevant departments and have completed installation or installing solar power generation equipment at main business sites in Japan, and also progressing with installation at business sites overseas.

- We have also started inspecting raw materials affected by carbon neutrality and evaluating substitute materials. Procurement of green chemicals involves securing a source of bio-PE, ensuring a supply volume of lignin and furfuryl alcohol, and examining bio-based phenol and bio-based methanol markets. In addition, with the aim of sustainable procurement of raw materials, we changed some raw materials from animal oils to vegetable oils and fats.

Initiatives for Stable Procurement

- The Global Procurement Division conducts audits of our raw material manufacturers. In many cases, quality audits are carried out at the same time as those conducted by production and quality departments. However, audit items and assessment criteria are unique to the Global Procurement Division and are used for auditing supply stability. We investigate the status of the entire company, the relevant business, raw material procurement, facilities, locations, manufacturing sites, workers, and relationships with our company to make comprehensive assessments during audits. If it is determined that improvement is necessary, we indicate to the supplier in writing what needs to be improved and ask them to respond by a given deadline.

- Furthermore, the Global Procurement Division conducts BCP verification of raw materials manufacturers and prepares a list of locations of materials manufacturers and keeps it up to date. In the event of a disaster, the division checks the statuses of manufacturers’ factories in the affected areas and formulates countermeasures.

Sustainable Procurement Training for Procurement Division Employees

- In October 2024, we provided training to 17 members of our Global Procurement Division covering the significance and benefits of sustainable procurement, examples of social and environmental issues in the supply chain (child labor, forced labor, poor working conditions, bribery, environmental destruction, etc.), and procedures and methods for sustainable procurement.

Sustainable Procurement Questionnaire Survey

- In fiscal 2023, we conducted a questionnaire survey of 114 major suppliers, which account for the top 90% of raw material purchases by segment, and received responses from 107 companies.

- This survey was conducted using the “Responsible Business Conduct Guidelines / Self-Assessment Questionnaire Detailed Version” developed by JEITA (Japan Electronics and Information Technology Industries Association). And the self-evaluation therein was conducted in nine areas with each item rated on a 100-point scale: “1. Compliance with Laws and Regulations and Respect to International Norms, 2. Human Rights and Labor, 3. Health and Safety, 4. Environment, 5. Fair Trade and Ethics, 6. Quality and Safety, 7. Information Security, 8. Business Continuity Plan, and 9. Establishment of Management System.”

- As a result of this survey, we requested the 16 target suppliers whose responses include items that fall below the prescribed criteria to make improvements, and we will establish a system that allows for more appropriate procurement.

Survey Results

| Coverage | Result | (Target) | |

|---|---|---|---|

| Fiscal 2023 | (Fiscal 2024) | ||

| Sustainable procurement rate (%)*1 | Group*2 | 82% | (≧85%) |

- *1 The percentage of suppliers whose responses to the sustainable procurement questionnaire that meet the specified criteria among the major suppliers accounting for the top 90% of raw material purchases by segment

- *2 Sumitomo Bakelite Co., Ltd. and the companies in which Sumitomo Bakelite Co., Ltd. directly or indirectly holds more than 50% of the voting rights

| Item | Fiscal 2023 Average Score |

Item | Fiscal 2023 Average Score |

|---|---|---|---|

| 1. Compliance with Laws and Regulations and Respect to International Norms | 92 | 6. Quality and Safety | 99 |

| 2. Human Rights and Labor | 86 | 7. Information Security | 78 |

| 3. Health and Safety | 87 | 8. Business Continuity Plan | 76 |

| 4. Environment | 96 | 9. Establishment of Management System | 82 |

| 5. Fair Trade and Ethics | 91 | Average of all Items | 88 |

- Please see the link below for the details on our sustainable procurement questionnaire survey.

Response to Responsible Mineral Sourcing

Promoting Responsible Mineral Sourcing

- There is a concern that the use of minerals such as tin, tantalum, tungsten, gold, cobalt, and mica that are mined in “Conflict-Affected and High-Risk Areas (CAHRAs),” including the Democratic Republic of the Congo (DRC) and its adjoining countries may lead to financing armed groups, human rights violations including forced labor and child labor, environmental destruction, money laundering, corruption, tax evasion, and other fraudulent activities (OECD Annex II Risks).

- Our Group will conduct appropriate assessments (due diligence) based on the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD DD Guidance)” to ensure that the use of minerals that could lead to fraudulent activities are not used in our Group’s products.

Responsible Mineral Sourcing Policy for the Group of Sumitomo Bakelite Co., Ltd. (Established on October 1, 2023)

-

We, Group of Sumitomo Bakelite Co., Ltd. is committed to promoting responsible mineral sourcing in taking the following actions, in order to prevent “financing armed groups, human rights violations including forced labor and child labor, environmental destruction, money laundering, corruption, tax evasion, etc. (OECD Annex II Risks)” in the “Conflict-Affected and High-Risk Areas (CAHRAs),” including the Democratic Republic of the Congo (DRC) and its adjoining countries, when using raw materials and parts containing tin, tantalum, tungsten, gold, cobalt, or mica:

- We will manage our supply chain appropriately in accordance with the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD DD Guidance).”

- We will request our suppliers to source the covered minerals from smelters/refineries that comply with the Responsible Minerals Assurance Process (RMAP) promoted by the Responsible Minerals Initiative (RMI).

- We will use the covered minerals that are not associated with the OECD Annex II Risks, even if they are produced or refined from CAHRAs. This does not mean that we will not use any covered minerals produced or refined/refined from CAHRAs uniformly.

- We will request corrective action through our suppliers, if we discover the possibility of OECD Annex II Risks in our supply chain. We will consider the possibility of suspending transactions depending on the status of corrective action.

- We will share our Group’s “Procurement Policy” and “Responsible Mineral Sourcing Policy” with our suppliers, will request our suppliers to provide information regarding smelters/refineries through the supply chain, and will strive to engage in dialogue and collaboration with our suppliers to contribute to eliminating and reducing the OECD Annex II Risks under CAHRAs.

Framework of Initiatives

-

Our Group implements initiatives in line with the “Five-Step Framework for Risk-Based Due Diligence in the Mineral Supply Chain” in the OECD DD Guidance.

[STEP 1 Establish strong company management systems]

- Our Group established the “Responsible Minerals Sourcing Policy for the Group of Sumitomo Bakelite Co., Ltd.” and has establishes a system to manage whether or not there are any OECD Annex II Risks in CAHRAs for the covered minerals contained in our Group’s products, by using the industry standard methods (Conflict Minerals Reporting Template (CMRT), Extended Minerals Reporting Template (EMRT) and RMAP issued by RMI).

[STEP 2 Identify and assess risks in the supply chain]

- Our Group regularly identifies the raw materials and parts that require investigation from the raw materials and parts we purchase, and conducts investigations to identify smelters and refineries using the CMRT/EMRT issued by RMI. In such investigations, we confirm whether or not tin, tantalum, tungsten, gold, cobalt, and/or mica is intentionally added or used, confirm the country of origin, and identify the smelter/refinery (including confirming whether it is listed on the RMAP conformanet smelter/refinery list).

- Both CMRT and EMRT are designed so that the answer unit can be selected from “(1) Company,” “(2) Product (or List of Products)” or “(3) User defined.” However, in order to confirm the smelter/refinery of the minerals contained in the parts and materials used in our Group’s products reliably, we request our suppliers to respond by specifying the products.

- In addition, our Group conducts similar surveys when adopting new raw materials.

[STEP 3 Design and implement a strategy to respond to identified risks]

- In order to continuously reduce risks, our Group regularly develops a responsible mineral sourcing survey plan, and re-surveys and updatesthe latest information.

- If there is a concern that a supplier uses a smelter/refinery with the high OECD Annex II Risks, our Group will communicate the details of such risk and proceed with appropriate measures for improvement while consulting with the supplier. Additionally, if the relationship between the supplier and the OECD Annex II risk becomes clear, we will consider suspending transactions with that supplier.

[STEP4 Carry out independent third-party audit of smelter/refiner’s due diligence practices]

- Our Group requests its suppliers to procure target minerals from the smelters/refineries listed on the RMAP compliant smelters/refineries list. The audit to become an RMAP conformant smelters/refineries must be conducted by an independent third party.Co., Ltd.

[STEP 5 Report annually on supply chain due diligence]

- Our Group will publish a report on our responsible mineral sourcing activities on our website

Survey Results

-

Fiscal 2023 Responsible Minerals Sourcing Survey Results

[Tin, Tantalum, Tungsten, Gold (3TG)]

- Our Group conducted a survey using CMRT of 16 suppliers that handle 34 raw materials and parts containing or adding tin, tantalum, tungsten, and or (3TG). The CMRT response rate was 100% and the RMAP conformant smelter usage rate was 100%.

[Cobalt, Mica]

- Our Group conducted a survey using EMRT on eight suppliers that handle eight product numbers of raw materials and parts containing or adding cobalt or mica. Although the EMRT response rate was 100%, there are issues that are difficult for our Group to address alone, such as the following: - S ome suppliers may not cooperate with disclosure of smelter/refinery information because the investigation is not required by laws and regulations; and - The number of RMAP conformant smelters/refineries for cobalt and mica (especially mica) is small.

| Coverage | Mineral | Result | (Target) | ||

| Fiscal 2023 | Fiscal 2024 | ||||

| Responsible Mineral Sourcing Survey Results 3TG (tin, tantalum, tungsten and gold) |

Group*1 | 3TG Total |

Number of raw materials/parts | 34 | - |

| CMRT response rate | 100% (16/16 companies) |

(100%) | |||

| RMAP conformant smelters usage rate*2 |

100% (101/101 locations) |

(100%) | |||

| Tin | Number of raw materials/parts | 31 | - | ||

| CMRT response rate | 100% (13/13 companies) |

- | |||

| RMAP conformant smelters usage rate*2 |

100% (98/98 locations) |

- | |||

| Tantalum | Number of raw materials/parts | 0 | - | ||

| CMRT response rate | - | - | |||

| RMAP conformant smelters usage rate*2 |

- | - | |||

| Tungsten | Number of raw materials/parts | 2 | - | ||

| CMRT response rate | 100% (2/2 companies) |

- | |||

| RMAP conformant smelters usage rate*2 |

100% (2/2 locations) |

- | |||

| Gold | Number of raw materials/parts | 1 | - | ||

| CMRT response rate | 100% (1/1 company) |

- | |||

| RMAP conformant smelters usage rate*2 |

100% (1/1 location) |

- | |||

| Responsible Minerals Sourcing Survey Results Cobalt, Mica |

Group*1 | Cobalt | Number of raw materials/parts | 4 | - |

| EMRT response rate | 100% (4/4 companies) |

- | |||

| Mica | Number of raw materials/parts | 4 | - | ||

| EMRT response rate | 100% (4/4 companies) |

- |

- *1 Sumitomo Bakelite Co., Ltd. and the companies in which Sumitomo Bakelite Co., Ltd. directly or indirectly holds more than 50% of the voting rights (Vaupell Holdings Inc. and its subsidiaries, Hokkai Taiyo Plastic Co., Ltd. and S.B. Techno Plastics Co., Ltd. were excluded in the fiscal 2023 survey)

- *2 RMAP:

RMAP conformant smelter usage rate = Number of RMAP Conformant Smelters / Total smelters x 100

Multiple smelters/refiners may be used for the same supplier and raw materials.

- Please see the link below for the details on our responsible mineral sourcing questionnaire survey.