Products

|

We offer our Phenolic molding compounds with 30 years over experience to meet customers' needs such as weight saving, cost saving and design flexibility. Plants

Laboratories

|

LCA Study

Here are some examples of LCA studies of applications in which our phenolic molding compounds are used.

These are LCA examples of brake pistons and pulleys for automobiles made of phenolic molding compounds.

We use MiLCA, a globally recognized LCA calculation module for calculation. Please contact us for more information.

CO2 Emissions of Composite Automotive Parts

Phenolic Brake Pistons

| CO2 emissions per 1 kg of product (kg-CO2e/kg) |

CO2 emissions per 1 product (0.2 kg) (kg-CO2e/kg) |

|

|---|---|---|

| Molding Material (Molding Material and its Raw Material) |

1.62 | 0.32 |

| Parts Manufacturing (Molding process) |

0.24 | 0.05 |

| Sum | 1.86 | 0.37 |

| Disposal (incineration, recycling, etc.) |

Our Environmentally Friendly Technology Brings Them Closer To Zero. | |

CO2 emissions related to parts production amount to 0.925 kg-CO2eq per vehicle*.

(* Estimated at an average of 2.5 pc/vehicle)

Phenolic compounds are expected to reduce CO2 emissions

due to the difference in production methods from conventional materials.

|

Remark

|

Calculation Conditions Data Base: IDEA v2.3 |

Using MiLCA, LCA of automotive molded parts can now be calculated. Please use this information for comparison with your company's current parts.

Phenolic Automotive Pulleys

| CO2 emissions per 1 kg of product (kg-CO2e/kg) |

CO2 emissions per 1 product (0.2 kg) (kg-CO2e/kg) |

|

|---|---|---|

| Molding Material (Molding Material and its Raw Material) |

3.24 | 0.65 |

| Material: Materual Insert | 2.62 | 0.26 |

| Parts Manufacturing (Molding process) |

0.35 | 0.10 |

| Sum | 6.21 | 1.01 |

| Disposal (incineration, recycling, etc.) |

Our Environmentally Friendly Technology Brings Them Closer To Zero. | |

CO2 emissions related to parts production amount to 1.01 kg-CO2eq per vehicle.*

(* Estimated at an average of 1.0 pc/vehicle)

Phenolic compounds are expected to reduce CO2 emissions

due to the difference in production methods from conventional materials.

|

Remark

|

Calculation Conditions Data Base: IDEA v2.3 |

Using MiLCA, LCA of automotive molded parts can now be calculated. Please use this information for comparison with your company's current parts.

Features

Non-ammonia material

Our high reliable non-ammonia grade has extremely low metal corrosion and excellent electrical properties.

Excellent solder heat resistance

High heat resistance over 400°C meets high cycle requirement in solder reflow process of SMT.

Non-halogen flame retardant materials

|

Many kinds of thermoplastics lose their mechanical strength to get non-halogen flame retardancy. Our non-halogen flame retardant phenolic molding compounds for transformer bobbin has high mechanical strength with cost-effectiveness. |

|

Tracking resistance (CTI:250V) compliant

Good balance of CTI (comparative tracking index) and mechanical strength for high frequency and high voltage requirement in electrical components.

Commutator materials

Excellent mechanical strength, heat resistance, humidity resistance and dimensional stability improve revolution at burst and bar-to-bar movement for noise reduction and brush wear. Processability such as slitting, press-fitting of shaft and fusing is also excellent.

High reliability

Outperform engineering thermoplastic with high heat resistance, rigidity at high temperature and good creep property at high temperature.

Good dimensional stability

Good transcription ability to cavity and good dimensional stability.

Wide range of design flexibility

Good moldability for wide range of thickness from thin parts (100microns) to thick parts (tens of mm), complicated shape or uneven thickness parts.

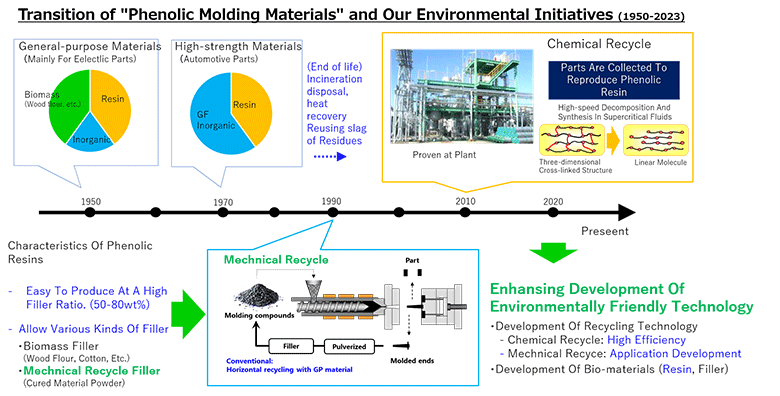

Environmental compatibility

| Environmental loading material free |

: | Asbestos free, halogen free |

|---|---|---|

| Recycle | : | Thermal recycle Material recycle |

| ※ | We develop the world's first Chemical Recycle Technology for Phenolics. |

|---|

Chemical Recycle Demonstration Plant (Shizuoka)

Applications

Electrical and Eelectronic Equipment

Electronic Component

Electronics

Transformer bobbins for SMT and circuit breakers

Electric

Home appliance

Switch cases and commutator for small motors

Automotive/Railways/Aircraft

Automotive Mechanical Components

Powertrain

Front End Accessory Drive Pulley, Cooling parts (water pump cover, impeller, thermostat housing, ...), transmission parts (AT stator, DCT valve block, hydraulic valve parts, ...)

|

|

Motor

Commutator, brush holder, slip ling, starter solenoid cover, ...

|

|

Chassis

Disc brake caliper piston, booster valve body, ...

Interior/exterior

Window regulator housing, air spring guide bush, ash tray, ...

Fuel control

Fuel pump impeller, fuel pump case, ...

Topics More

- 2024/12/26 Products Development of SUMIKON® AM-3800 - a Diallyl Phthalate (DAP) molding compound for high voltage (800V) and high heat resistance

- 2024/10/18 Products SNC Industrial Laminates Sdn. Bhd. (Malaysia) Expansion of Liquid Phenolic Resin Supply

- 2024/10/16 Products Development of Fire Resistance Phenolic Molding Compounds for EV Batteries

- 2024/05/14 Products Development and Sales of Cyclo-Olefin Polymers (COP) to Meet Diverse Needs

- 2024/04/02 Products Completion ceremony of the new plant for phenolic molding compounds at Sumitomo Bakelite (Nantong) Co., Ltd.

Inquiry

Inquiry