- TEL:

- +81-3-5462-4101

- FAX:

- +81-3-5462-4887

※9:00-17:40 Mon.-Fri. (JST)

|

SUMIMAC® ECR/ECH has excellent workability and safety and is widely used for electrical insulation of ignition coils, relays and sensor applications. Plants

Laboratories

|

|

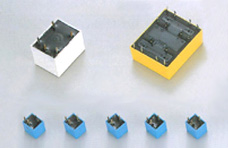

Application example: ignition coil impregnation

|

Application example: relay encapsulation

|

| ECR-9250K | ECR-9185K | ECR-9240K | ||

|---|---|---|---|---|

| Application | Relay | Relay | Sensor | |

| Advantage | Heat resistance | ● | ||

| Good adhesive strength | ● | ● | ● | |

| High strength | ● | |||

| Viscosity | Pa·s, 25°C | 35 | 46 | 7 |

| Specific gravity | - , 25°C | - | 1.4 | - |

| Color of cured material | Black | Black | Black | |

| Standard condition for curing | 100°C. 60min. or 120°C. 30min. | 100°C. 60min. or 120°C. 30min. | 120°C. 60min. | |

Remark

| ECR-2222K + ECH-222G | ||

|---|---|---|

| Application | Ignition coil package | |

| Advantage | Good impregnation ability | ● |

| Low temp. curing | ||

| Flame resistance | ||

| Mixing ratio (resin/hardener) | 100 / 100 | |

| Viscosity of mixture | Pa·s, 25°C | 0.5 / 60°C. |

| Specific gravity of mixture | -, 25°C | 1.7 |

| Color of cured material | Black | |

| Standard condition for curing | 100°. 2hr + 140°C. 2hr | |

Remark