Basic Approach and Policy

Our Group believes that ensuring the occupational health and safety of employees is the cornerstone of our business activities. We established the “Safety Action Guidelines” based on the safety philosophy of “Safety is the first priority of all,” and ensuring that everyone, including our employees and subcontractors, focuses on achieving an accident- and disaster-free record to eliminate various hazardous or toxic factors from the workplace.

Occupational Health and Safety Policy

- We will continue safe and stable operations by pursuing zero Occupational Accident based on our safety principle of “Prioritizing Safety in Everything We Do.”

- We will ensure the safety of our stakeholders including employees and local communities by continuously improving occupational health and safety, accident prevention, and other safety-related issues based on risks.

Application: All Sumitomo Bakelite Group business sites and subsidiaries in Japan and overseas

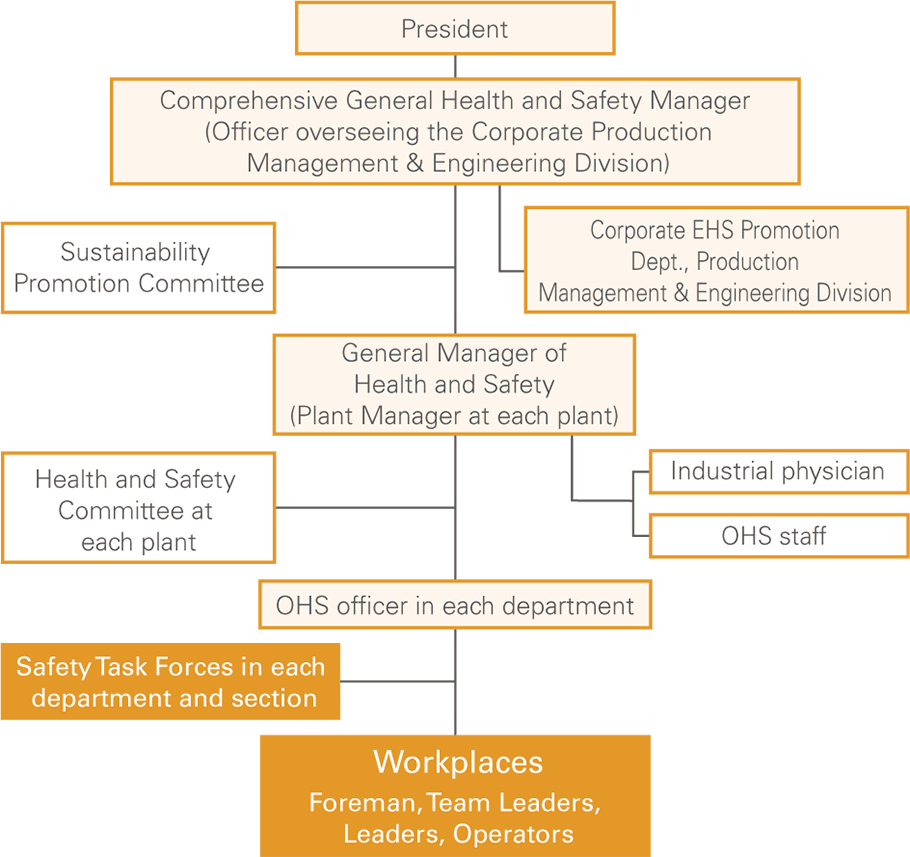

Occupational Health and Safety Management System

Our Group has established the “Sustainability Promotion Committee” chaired by the President. This committee determines health and safety policies along with important measures for preventing accidents and disasters, and based on these, rolls out health and safety activities across the entire Group.

In addition, we enacted our uniform, company-wide Safety Philosophy “Safety is the First Priority of All” and our three Safety Action Guidelines in October 2019 and Machine Safety Guidelines in December 2023 to promote the complete elimination of fatal accidents and serious disasters.

Each of our business sites makes efforts closely in tune with the needs of individual workplaces within a company-wide framework and under an accountability structure involving the managers of business sites. At its monthly meetings, the Health and Safety Committee reviews health and safety management activities, ensures thorough compliance with relevant laws and ordinances, and considers capital investments to realize risk reduction, among other actions.

Our Group’s plants and main subsidiaries in Japan have been pursuing ISO 45001 accreditation since 2009, followed by our Group’s overseas subsidiaries from 2010. Today, a total of 25 business sites have received accreditation, which include six business sites and three subsidiaries in Japan and 16 subsidiaries overseas.

Machinery and Equipment Risk Reduction Activities

All new machinery and equipment installed at domestic production plants and subsidiaries from 2008 and at overseas subsidiaries from 2009, have been designed in compliance with ISO 12100. We carry out risk assessments of existing machinery and equipment when changes occur, such as when modification is made to them or the work procedure is updated. To promote further safety, we established Machine Safety Guidelines to ensure the fundamental safety of machinery and equipment.

Risk Reduction Activities relating to Chemical Substances

In 2012, we introduced chemical substance risk assessments at plants in Japan and subsidiaries worldwide. We reassess the risk assessment results when changes occur, such as information on the risks and hazards posed by chemical substances and work procedure revision. This is done with the in aimof preventing adverse health effects to employees through exposure to chemical substances and to prevent explosion or fire incidents caused by chemical substances.

Complaints from Authorities, Local Governments, and Local Communities

Our business sites in Japan along with subsidiaries worldwide comply with laws and ordinances and address prevention needs in order to preserve the environment.

In fiscal 2023, we received a noise complaint from a nearby resident at an overseas plant. After analyzing the cause of the noise, we made improvements and confirmed that the noise level was within the legal standard, taking appropriate responses such as contacting the regulatory agency about the results of the improvement.

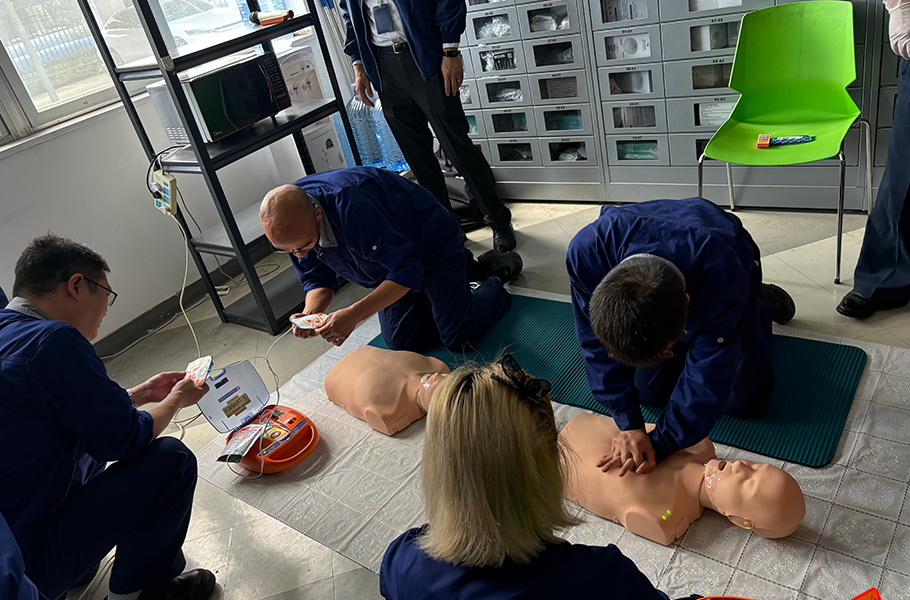

Health and Safety Education

We carry out measures to reduce the risks posed by machinery and chemical substances in order to ensure safety at sites where these are used. At the same time, we conduct hazard prediction training as well as initiatives, such as “pointing and calling” and making proposals for reducing near-miss accidents. We have introduced “Anzen Dojo (Safety Gyms)” at each production plant to allow employees to learn about the fundamentals of safety. We are able to improve our safety consciousness and learn hazard prediction skills and risk identification skills.

Health and safety activities in which plant managers take the lead and act as role models form the basis for specialized safety education for managers, education on laws and regulations for mid-level employees, and hands-on education for new employees regarding safety. In addition, we make efforts to disclose disaster and accident information, and share them in a timely manner through the use of our Safety Portal Site, which was set up online to be accessible by every employee. In addition, health and safety education has been implemented at all business sites by using video materials such as a video that outlines our approach to Safety Philosophy and Safety Action Guidelines and a VR device.

Educating new recruits on safety

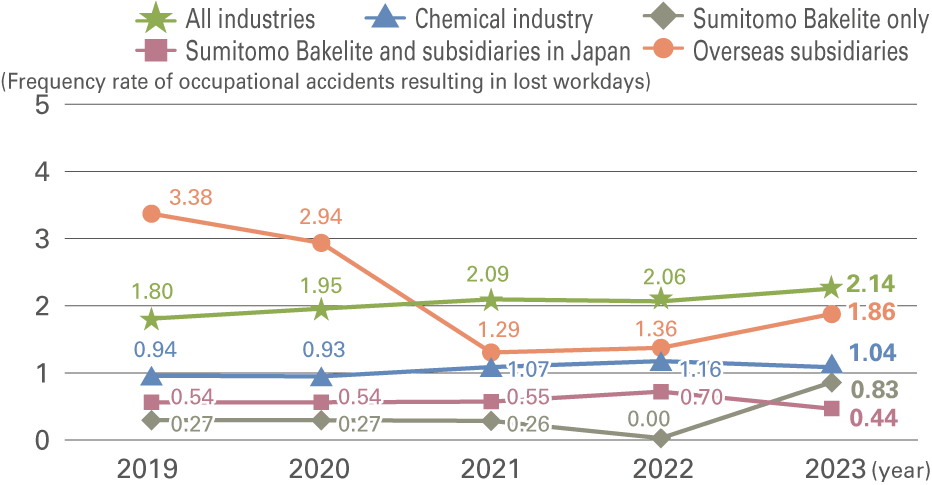

Occupational Accident Figures

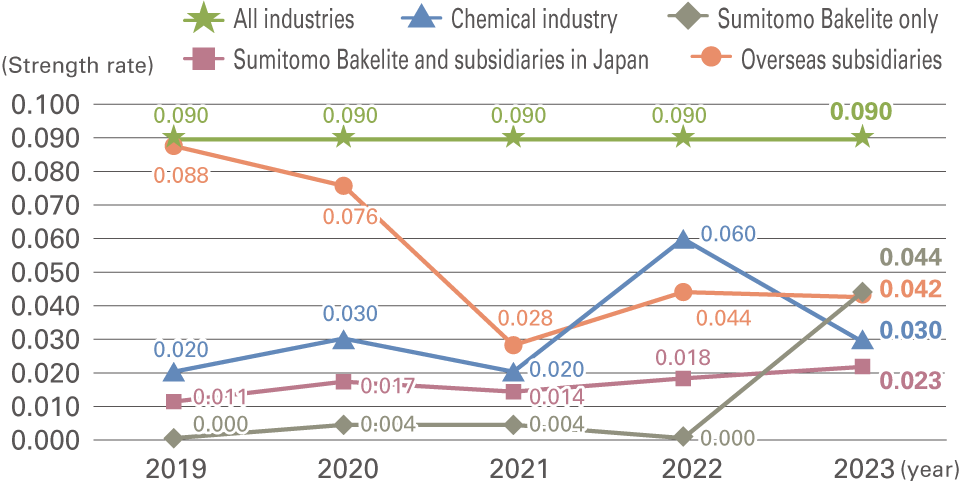

Trends in the Frequency Rate and Severity Rate of Occupational Accidents at Sumitomo Bakelite Co., Ltd. and Subsidiaries Worldwide

The graph below shows the overall frequency rate and severity rate*1 of occupational accidents including those occurring at subsidiaries worldwide.

In Japan, the frequency rate was improved by the reduction of occupational accidents resulting in lost workdays but the severity rate worsened due to serious accidents occurring. Meanwhile, the frequency rate worsened overseas due to increase in the number of occupational accidents resulting in lost workdays but the severity rate remained the same.

| *1 | Frequency Rate of Occupational Accidents = (Number of deaths and injuries resulting in lost workdays/total working hours) x 1,000,000 Severity Rate of Occupational Accidents = (Total lost workdays/total working hours) x 1,000 |

|---|---|

| * | The period covered is from January to December of each year. |

| * | Total number of hours worked Sumitomo Bakelite Co., Ltd. only: 3,265,203 hours Sumitomo Bakelite Co., Ltd. and subsidiaries in Japan: 6,884,572 hours Overseas subsidiaries: 12,370,807 hours |

● Frequency Rate of Occupational Accidents Resulting in Lost Workdays at Sumitomo Bakelite Co., Ltd. and Subsidiaries Worldwide

- * The independent assurance covers the frequency rates of

Sumitomo Bakelite Co., Ltd. only, as well as our Japanese and overseas subsidiaries.

● Severity Rate of Occupational Accidents at

Sumitomo Bakelite Co., Ltd. and Subsidiaries Worldwide

- * The independent assurance covers the frequency rates of

Sumitomo Bakelite Co., Ltd. only, as well as our Japanese and overseas subsidiaries.

Trends in Occupational Accidents at Sumitomo Bakelite Co., Ltd. and Subsidiaries

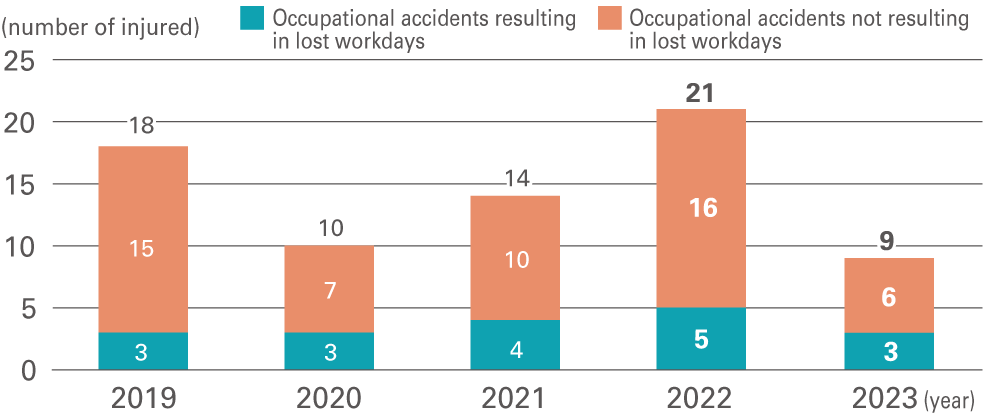

Number of Employees Injured due to Occupational Accidents

The graph below shows the number of employees injured due to occupational accidents at our company as well as subsidiaries in Japan.

In 2023, there was only one occupational accident resulting in lost workdays that occurred at a subcontractor. And also, there was one case of severe injury requiring six months or more to recover and resulting in permanent disabilities.

- * Total working hours of subcontractors: 626,230 hours

● Number of Employees Injured due to Occupational Accidents (in Japan)

- * The period covered is from January to December of each year.

- Data from SB Kawasumi Laboratories Inc. (three domestic plants) are added from 2021.

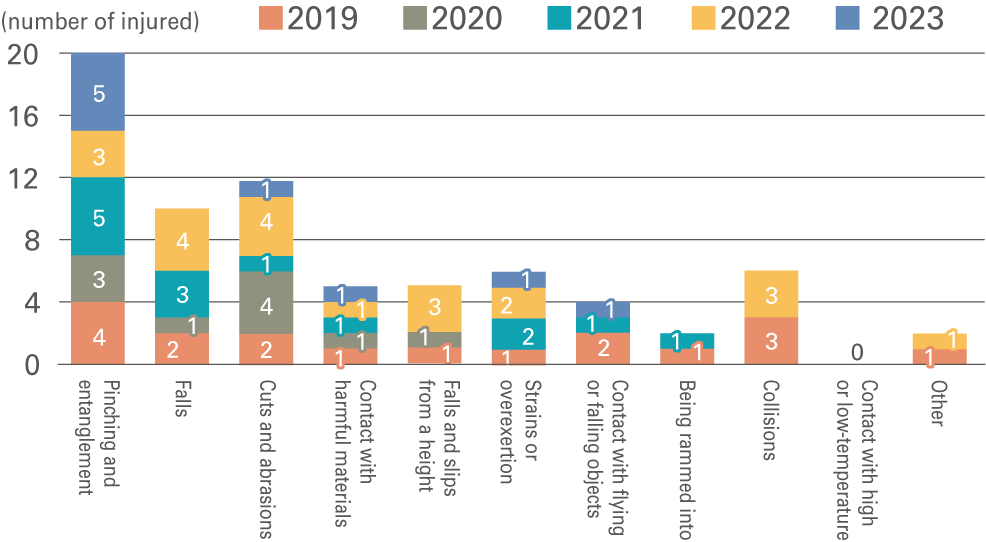

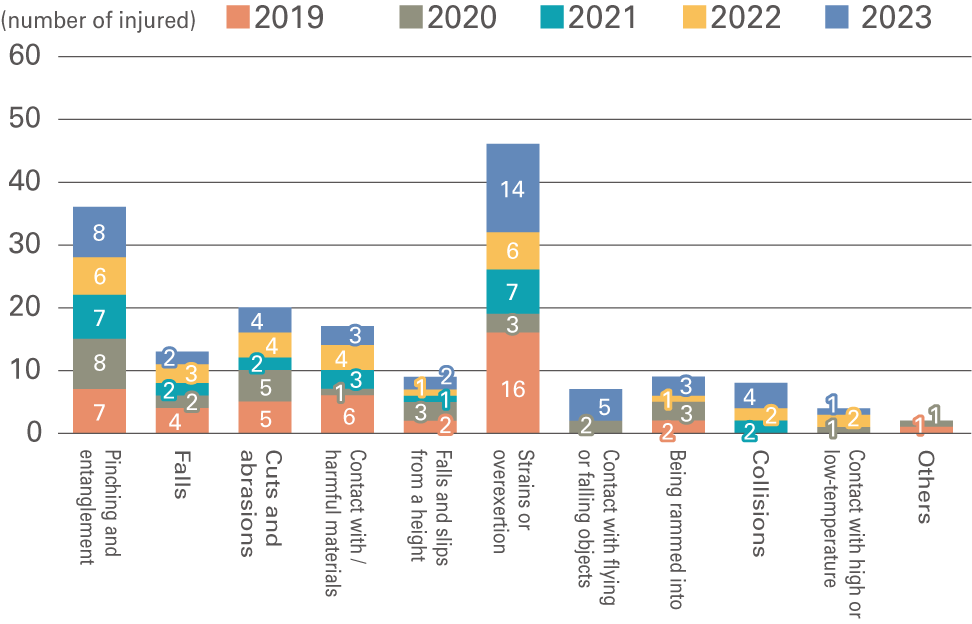

Occupational Accidents by Type

Occupational accidents in Japan categorized by type are shown in the graph below.

As the majority of the pinching and entanglement accidents in 2023 were caused by insufficient safety measures for machinery, we have formulated the Machine Safety Guidelines and have been promoting safety measures following ISO 12100.

In the event of an accident, a risk assessment is conducted and corrective measures are implemented based on the results of investigations into the cause, and efforts are made to prevent the recurrence of similar accidents.

● Occupational Accidents by Type (in Japan)

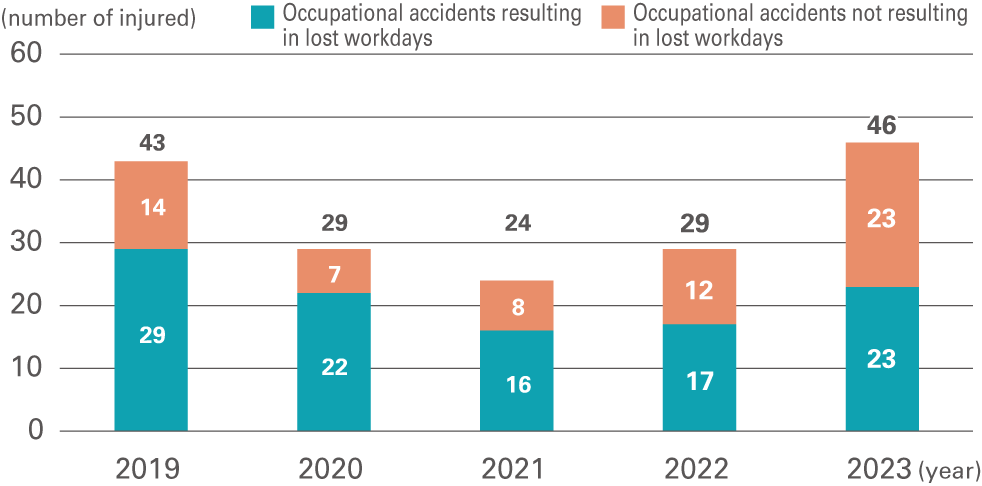

Trends in Occupational Accidents at Overseas Subsidiaries

Number of Employees Injured due to Occupational Accidents

The graph below shows the number of employees injured due to occupational accidents at our overseas subsidiaries.

In 2023, there was only one occupational accident resulting in lost workdays that occurred at a subcontractor. In 2023, there were no cases of deaths or severe injuries resulting in permanent disabilities but there was one case of severe injury requiring six months or more to recover.

- * Total working hours of overseas subcontractors: 653,284 hours

● Number of Employees Injured due to Occupational Accidents (Overseas)

- * The period covered is from January to December of each year.

Data from SB Kawasumi Laboratories Inc. (two overseas plants) are added from 2021.

Occupational Accidents by Type

Occupational accidents overseas categorized by type are shown in the graph below.

As the majority of the accidents were caused by human factor such as 'overexertion' in 2023, we have prepared safety educational materials in multiple languages (English, Chinese) and have been promoting SB Safety Action Guidelines among all employees by using the explanatory video, aiming to raising awareness of safety to the same level as in Japan.

In the event of an accident, risk assessment and corrective measures are conducted based on the results of investigations into the cause, and efforts are made to prevent the recurrence of similar accidents.

● Occupational Accidents by Type (Overseas)

[TOPIC] Award for Zero Accidents

The following business sites were recognized for their initiatives toward safety, for which President Fujiwara presented certificates of commendation at the online awards ceremony.

- Sumitomo Bakelite (Shanghai) Co., Ltd. has gone a year and 1 million consecutive hours without an accident.

- Vaupell China (Dongguan) Co., Ltd. and Sumitomo Bakelite (Dongguan) Co., Ltd. has gone a year and 1 million consecutive hours without an accident.

- Sumitomo Bakelite Singapore Pte. Ltd. has gone 1 million consecutive hours without an accident.

- Kawasumi Laboratories (Thailand) Nava Nakron Plant have gone 2 years and 3 million consecutive hours without an accident.

We will continue to implement initiatives in line with our Groupʼs Safety Philosophy and Safety Action Guidelines to achieve even more accident-free operations by promoting improvements through the concerted efforts of all employees.

Online award ceremony for Sumitomo Bakelite (Shanghai) Co., Ltd.

Commemorative photo of members of Sumitomo Bakelite Singapore Pte. Ltd.

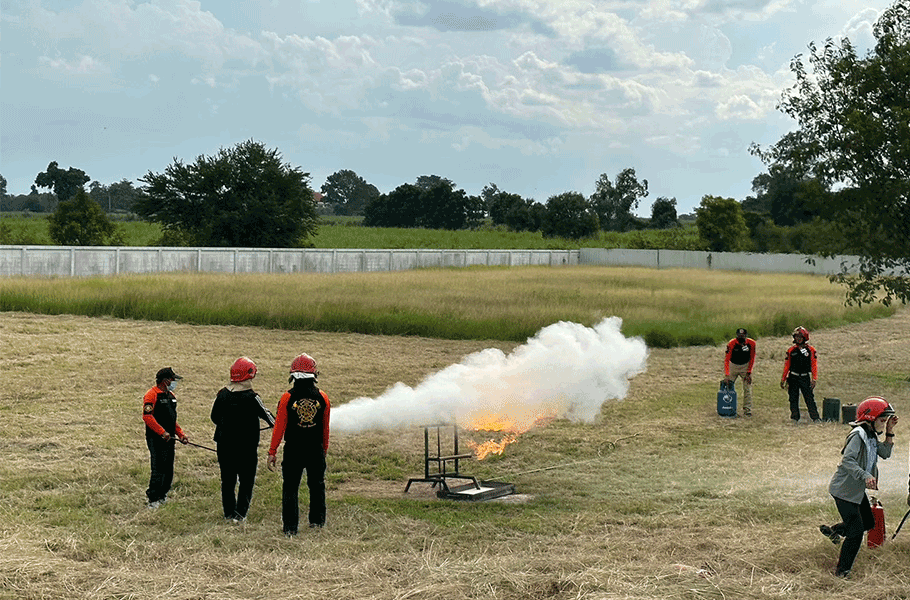

Security and Disaster Prevention

Accident prevention is the top priority of all our business sites. Our objective is to make business safer and more secure, and thus earn the confidence of the local community, ensure employee safety, and maintain stable supplies of products to customers. The Disaster Prevention Committee is convened and implements activities systematically with the aim of helping all business sites achieve zero accidents record. It also conducts emergency drills and puts in place accident prevention measures to minimize damage in the event that an accident does occur.

Sumitomo Bakelite Singapore Pte. Ltd. |

Sumitomo Bakelite (Suzhou) Co., Ltd. |

Kawasumi Laboratories (Thailand) Co., Ltd. (Korat Plant) |

Durez Corporation (Niagara Falls Plant) |

Durez Canada Co., Ltd. |

Shizuoka Plant |

Sumitomo Bakelite (Nantong) Co., Ltd. |