Products

|

Carrier tape base materials for semiconductors and electrical components packing for SMT process. Plants

Laboratory

|

Features

Tearing-free at high speed mounting process

No tearing at high-speed mounter by high endurance material. (If used under proper sealing/peeling condition)

Wide sealing operation range

Required peeling strength can be obtained since our cover tape is not dependent much on sealing temp and pressure.

Superior sealing stability

Small aged deterioration of peel strength after sealing. High stronger reliability at high temp and humidity

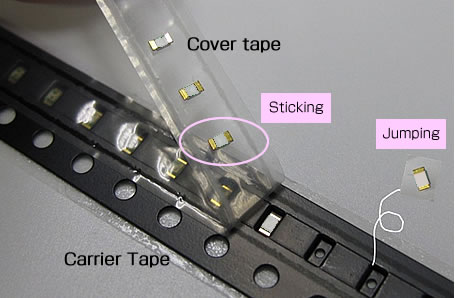

Trouble shooting in surface mount process

|

We, Sumitomo Bakelite Co., Ltd. can provide total solution to prevent from devices sticking to cover tape film surface or devices jumping/migration from carrier tape pocket. Please feel free to contact us without hesitation. |

|

Applications

Electrical and Electronic Equipment

Electrical Components Packing

Cover Tape for Semiconductors and Electronic Components Devices

Reel-form packing for Semiconductors such as QFP, SOT and CSP, Electronic Components such as LED, Capacitor, Resistor, Connector, and Crystal Oscillator.

Specifications

| Item | Unit | Method | Type | ||

|---|---|---|---|---|---|

| CSL-Z7302 Standard |

CSL-Z7500 Excellent Triboelectric Charge Performance |

||||

| Tensile Strength | MPa | JIS K6734 | 92 | 92 | |

| Luminous Transmittance |

% | JIS K7105 | 87 | 87 | |

| Haze | % | JIS K7105 | 25 | 22 | |

| Surface Resistivity |

PET | Ω | IEC61340 ANSI ESD STM11.13 23°C×50%RH |

10 10_11 | 10 10_11 |

| SEAL | 10 8_9 | 10 7_8 | |||

| PET | IEC61340 ANSI ESD STM11.13 23°C×30%RH |

10 10_11 | 10 10_11 | ||

| SEAL | 10 8_9 | 10 7_8 | |||

| PET | IEC61340 ANSI ESD STM11.13 23°C×12%RH |

10 11_12 | 10 11_12 | ||

| SEAL | 10 8_9 | 10 7_8 | |||

| Electrification voltage at Peeled Off |

V | SB *1 23°C×50%RH |

15 | 10 | |

| SB *1 23°C×30%RH |

140 | 65 | |||

| Triboelectric Charge | nC | SB *2 23°C×30%RH |

0.25 | 0.02 | |

Remark

- The data given above are not guaranteed values.

- SB Method

*1) Electrification voltage which is measured when cover tape is peeled off at a speed of 0.1sec/tact.

*2) Triboelectric Charge which is measured when resin for molding is vibrated on cover tape at 600 rpm for 5 minutes - *3) Enhanced Surface Resistance on both side under Dry Condition

Topics More

- 2023/10/13 Products Acquisition of Film Business of Asahi Kasei Pax Corp.

- 2021/06/01 Products Announcement of Price Revision of film sheet products

Inquiry

Inquiry