August 1, 2024

Tokyo, Japan - August 1, 2024 Sumitomo Bakelite Co., Ltd. (TOKYO: 4203 HQ: Shinagawa-ku, Tokyo, President and Representative Director: Kazuhiko Fujiwara) has started sample shipment of High Thermal Conductive Silver Sintering Paste 150 W/m K for next-generation power semiconductors, aiming for mass production in December 2024. The use of this product makes it possible to replace lead solder (37% lead content), which has a high environmental impact. Furthermore, by applying this product to SiC power semiconductors, it will contribute to miniaturization and component reduction while enhancing the functions of power semiconductors.

Development Background

In recent years, power semiconductors have been used as electronic devices for controlling high power consumption in a wide range of applications, including converters/inverters for electric vehicles (EVs) and new energy applications such as solar and wind power generation systems, where the market is expected to expand. Against this background, demand for SiC power semiconductors, which have characteristics superior to those of Si, is growing.

SiC power semiconductors are often used at high power and have high heat generation. However, SiC is a material with high thermal conductivity, which makes it difficult to diffuse heat efficiently. For this reason, die attach materials that join substrates and chips require high heat dissipation. Lead solder has been widely used in die attach materials. However, the waste and liquid waste generated in the manufacturing process of solder can contain lead and other harmful substances, as well as heavy metals, resulting in a large environmental impact. In addition, the thermal conductivity of solder (25~60 W/m K) is insufficient for the heat dissipation required for SiC power semiconductors. To solve this problem, sintering silver paste is attracting attention as a high thermal conductivity material, and the market is expected to expand.

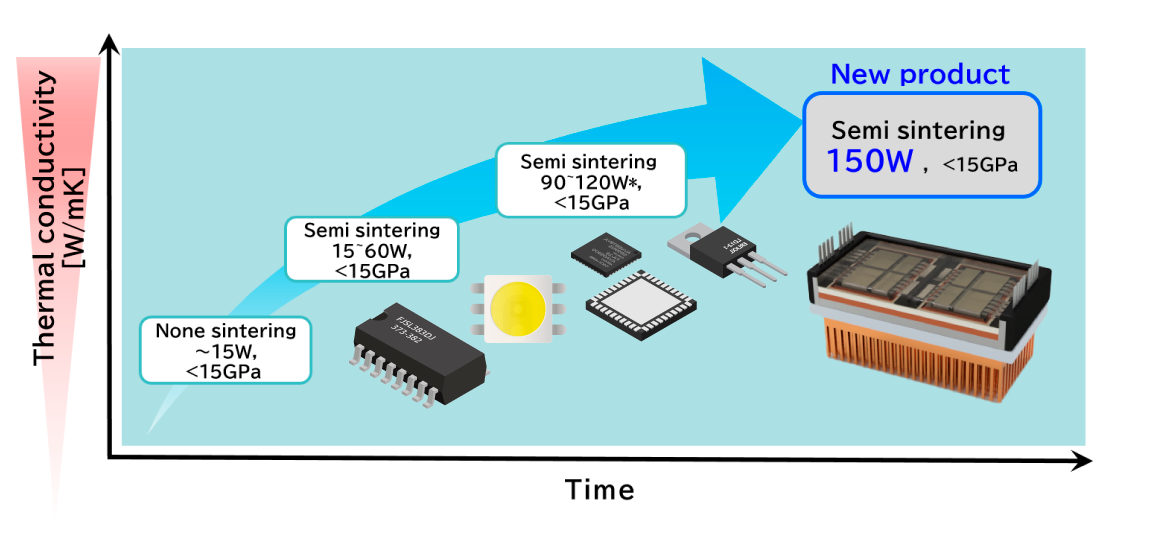

We have been working to achieve both high thermal conductivity and high reliability in sintering silver paste. Our Company has successfully developed a high heat dissipation semi-sintering silver paste with a thermal conductivity of 150 W/m K and started shipping samples.

High Thermal Conductivity Sintering Silver Paste for Power Semiconductors 150 W/m K

The silver paste developed using our resin compounding technology combines silver and resin, which has excellent flexibility and high sintering acceleration. With this resin technology, while having a high heat dissipation of 150 W/m K, it can be used in non-pressurized processes, and is expected to reduce damage to bonding components and shorten process time due to batch processing.

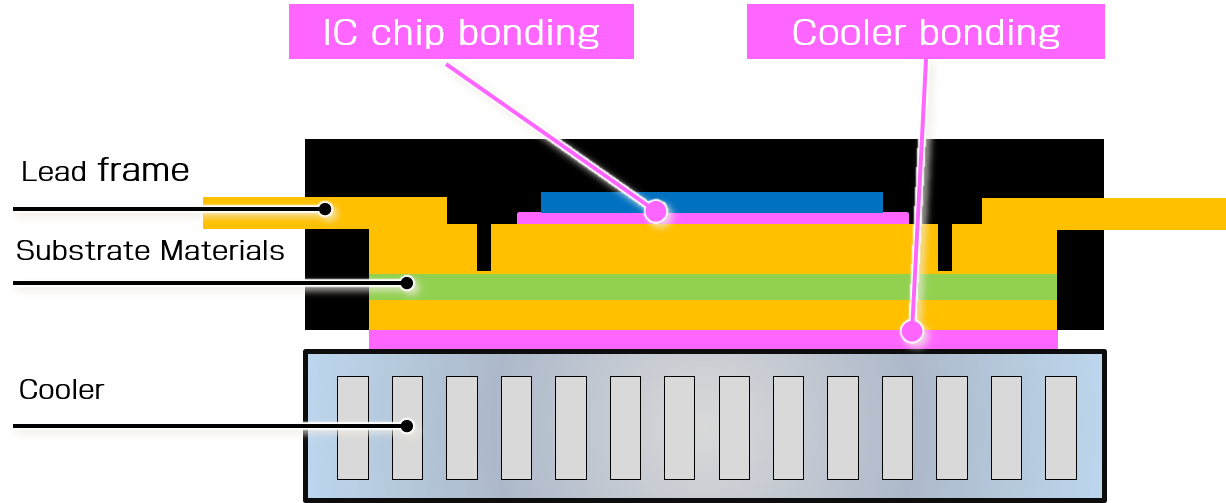

■ Parts expected to be used

In addition, this product has a lower curing temperature than conventional full sintering materials, which reduces stress due to differences in coefficient of linear thermal expansion between materials during curing process, and is excellent in bonding workability to multiple components with different heights contained in one package or module. It can be used as an alternative to solder and full sintering materials for bonding power semiconductor chips and coolers.

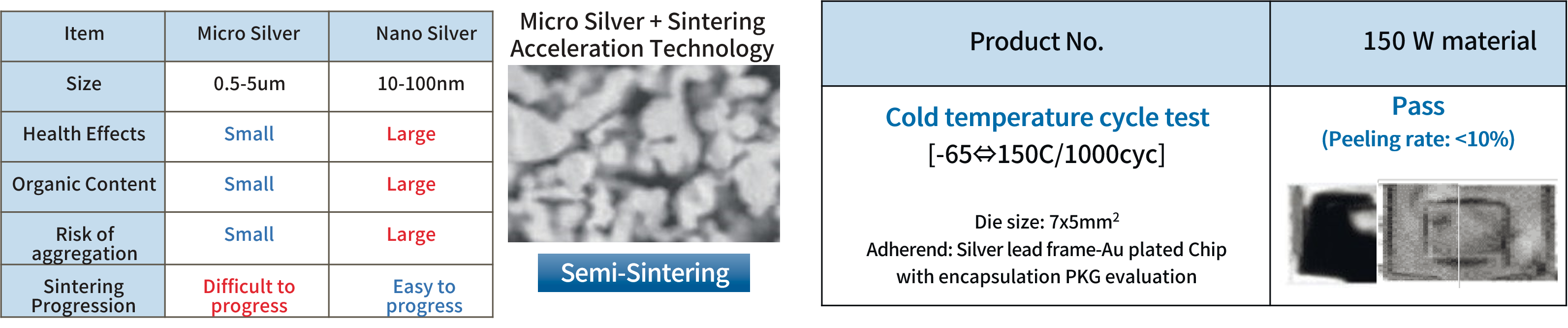

Micro silver, which is less expensive than nanosilver, can also be used to achieve high sinterability and high reliability due to the durability of cooling and temperature cycles.

Advantages of using this product

- Lead can be reduced by replacing lead solder (37% lead content) used in power semiconductors, etc.

- Reduction of stress by CTE differences due to low bonding temperature comparing to full sintering materials

- Improved bonding workability to multiple components with different heights in one package or modules

- Application to SiC semiconductors enables miniaturization of products and reduction of parts while enhancing functions

| Item | Solder | Silver full sintering material | Silver semi-sintering material |

|---|---|---|---|

| Required Thickness @ IC Chip Bonding |

20um | 70um | 20um |

| Bonding temperature | 225 degrees | 250 degrees | 200 degrees |

| Pressurization required/not required | Unnecessary | Required | Unnecessary |

| Material damage | Small | Large | Small |

| Cost/per PKG * | <<1 | >5 | 1 |

* Index when silver semisynter material is 1

- Part number characteristics are representative values

- Cooler bonding material: The required thickness tends to increase in the order of "silver full sintered > solder > silver semisynter material"

Realization of high thermal conductivity and high heat dissipation by resin technology and silver

Transition of development of high thermal conductive materials

Future plans

As for high thermal conductivity sintering silver paste 150 W/m K for power semiconductors, we started testing samples for customers in September 2023 and are evaluating the paste with customers. We aim to achieve mass production in December 2024.

Related Products

For inquiries on this information

Information & Telecommunication Materials Div.,

Sumitomo Bakelite Co., Ltd.

TEL: +81-3-5462-4105