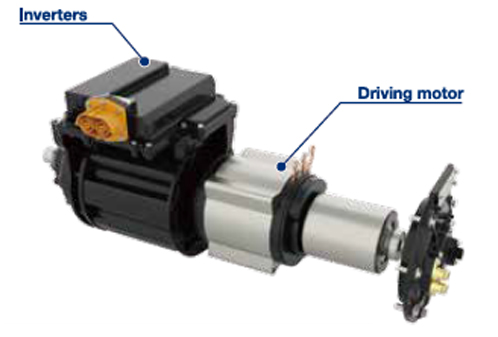

MobilityMiniaturization and Light Weight

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

Achieved process reduction and structural freedom through phenolic resin molding,

contributing to the miniaturization and weight reduction of metal substitute parts.

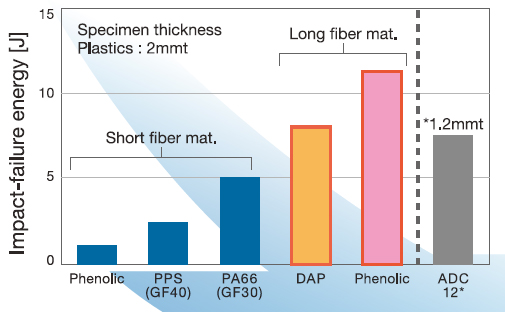

| Thermoset plastic | Thermoplastic | Aluminum die cast ADC12 |

||||

|---|---|---|---|---|---|---|

| Phenolic LF GF8210 |

DAP LF Developing |

PA66 SF GF45 |

PPS SF GF40 |

|||

| Specific gravity [-] | 1.8 | 1.9 | 1.5 | 1.7 | 2.7 | |

| Charpy impact st. (Notched) [kJ/m2] | 21 | 13 | 13 | 9 | - | |

| Flexural st. [MPa] | 25℃ | 260 | 175 | 295 | 225 | 350* |

| 120℃ | 210 | 125 | 165 | 140 | - | |

| Flexural mo. [GPa] | 25℃ | 19 | 17 | 13 | 14 | 65 |

| 120℃ | 16 | 13 | 6 | 7 | - | |

* *D.2% yield

Compatible impact strength to aluminum die cast

Phenolic (LF)

PPS GF40

ADC12

* based on JIS K7211-2 Plastics - Determination of puncture impact behaviour of rigid plastics

・Big electric component housing

・Structural member